-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

blog

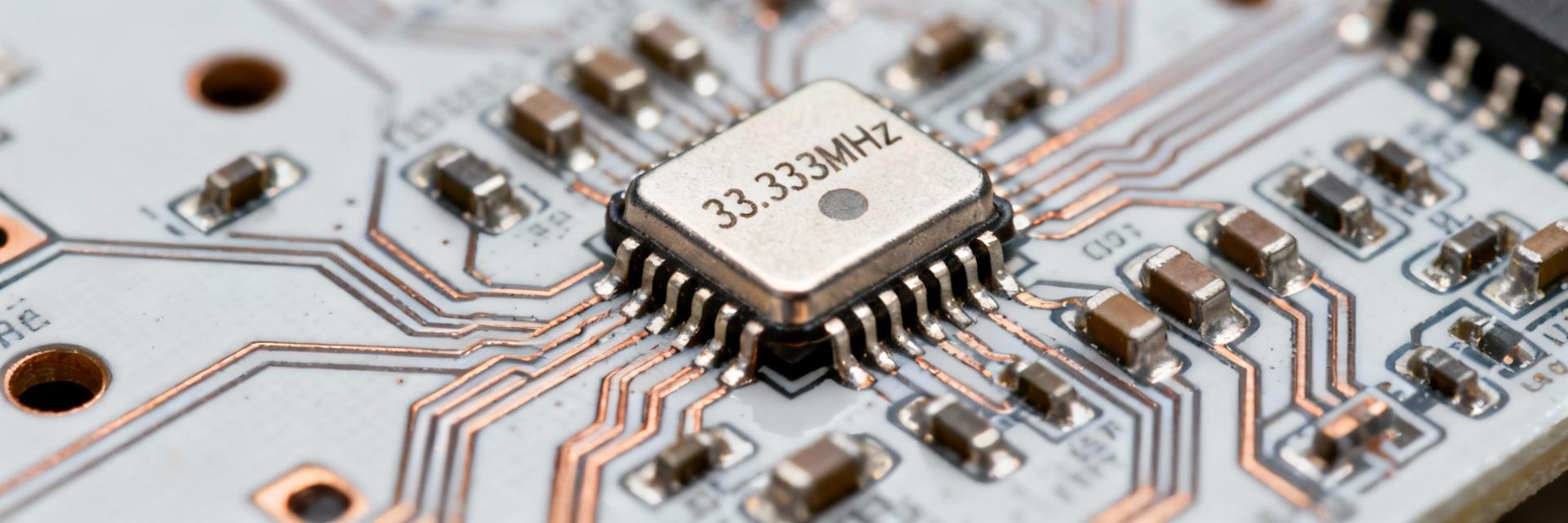

How to accurately match the 33.333MHz CMOS crystal oscillator for your project? Five-step pit avoidance guide

In high-speed communication, precision measurement, or audio/video processing projects, a seemingly simple 33.333MHz CMOS crystal oscillator selection can become the "Achilles' heel" of system stability. Frequency deviation, startup failure, signal jitter... these hidden traps are enough to stall the progress of an entire project. This article provides a clear, actionable five-step method to help engineers accurately match this "heart of the system," ensuring the project stays on the right track from the very beginning.

1

Deeply Understand Requirements, Define Selection Boundaries

The first step in selection is not to directly consult the parameter table, but to return to the project itself. You need to clearly define the role played by this 33.333MHz crystal oscillator and its performance boundaries. A clock source used for a Gigabit Ethernet PHY chip is significantly different in stringency compared to one used for an audio codec.

Application Scenario and Performance Metric Breakdown

First, clarify your application scenario. Is it used for synchronous data transmission (such as Ethernet, USB), or as a system clock for a microprocessor? The former has extremely high requirements for frequency accuracy and jitter, while the latter may focus more on long-term stability and cost. Key indicators include: initial frequency accuracy (e.g., ±10ppm), frequency stability over the operating temperature range, and the RMS value of phase jitter or period jitter. For example, high-speed SerDes interfaces typically require sub-picosecond jitter performance.

Initial Screening of Key Electrical Parameters (Frequency, Voltage, Load)

Three core points: 1) Nominal Frequency: Must be exactly 33.333MHz. 2) Supply Voltage: Typical voltages for CMOS output oscillators are 1.8V, 2.5V, 3.3V, etc., and must perfectly match the I/O voltage of the backend chip. 3) Load Capacitance: This is a key matching parameter for the CMOS output interface, requiring initial screening based on the chip's datasheet requirements.

2

Decrypting CMOS Output, Avoiding Interface Traps

CMOS output provides rail-to-rail square wave output with strong driving capability, but it also brings features like steep edges and rich harmonics, posing specific requirements for circuit design.

Output Type

Advantages

Challenges

33.333MHz Applicability

CMOS

Low cost, simple circuit, strong drive

Higher EMI, edge overshoot

Most mainstream choice

LVDS

Ultra-low power, strong anti-interference

Requires termination matching, more pins

Usually used for higher frequencies

Clipped Sine

Extremely low harmonics, good phase noise

Weak drive, requires shaping

Specific analog applications

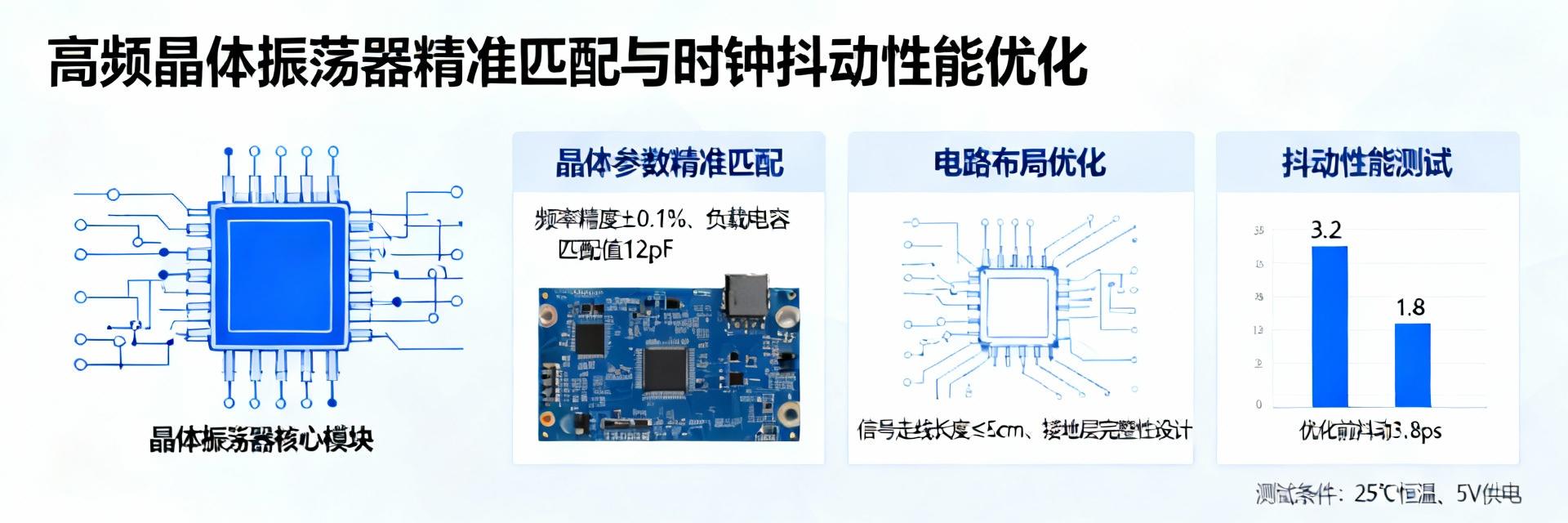

Matching Load Capacitance: Calculation and the Golden Rule of PCB Layout

The total load capacitance in the circuit is composed of parasitic capacitance, input capacitance, and external capacitance. The formula is: CL ≈ CPCB + CIN + (C1 * C2)/(C1 + C2). The PCB layout must be compact, with traces as short and straight as possible to reduce the uncertainty of CPCB.

3

Analyzing Stability and Accuracy, Locking in Core Parameters

Frequency Stability Visualization (±ppm)

Industrial Grade (±10ppm)Highest Accuracy

General Purpose (±30ppm)Balanced Performance

Consumer Grade (±50ppm)Cost Priority

Frequency stability refers to the maximum deviation of frequency within the operating temperature range. For example, a ±20ppm oscillator at 33.333MHz has a maximum deviation of ±666.66Hz. Aging rate is key to long-term reliability; the first-year aging of a high-quality oscillator is typically between ±1ppm and ±3ppm.

4

Practical Pitfall Guide—Five Common Traps and Countermeasures

Trap 1: Startup Failure or Slow Startup

Countermeasure: Check if the feedback resistor is in the megohm range; ensure load capacitance matches; verify power supply rise time to avoid slow ramping.

Trap 2: Excessive Clock Jitter Affecting High-Speed Interfaces

Countermeasure: Select Low Jitter models; optimize power supply decoupling (0.1μF + 0.01μF in parallel); keep clock traces away from noise sources.

Trap 3: Excessive EMI and Signal Integrity Issues

Countermeasure: Connect a small resistor (22Ω-100Ω) in series at the output to slow down edge speed; ensure a complete ground plane underneath.

Trap 4: Over-Sensitivity to Power Supply Noise

Countermeasure: Provide an independent LC or RC filter network; use an LDO rather than a switching power supply to power the oscillator.

Trap 5: Ignoring Mechanical Stress from Packaging and Soldering

Countermeasure: Strictly follow Land Pattern recommendations; avoid placing vias directly under the oscillator to reduce the risk of thermal stress damage.

5

Test Verification and Supply Chain Assurance

Sample testing is the final gate for validating selection. Use high-impedance probes to measure the clock waveform and observe rise/fall times. For high-speed applications, evaluate jitter through eye diagrams and check for spurs using a spectrum analyzer. Choose reputable suppliers and clarify consistency requirements for full-temperature range testing before bulk purchasing.

Key Summary

Requirements First

Precise matching begins with a clear definition of scenarios, accuracy, jitter, and voltage load.

Interface Matching

Understand CMOS characteristics, accurately calculate load capacitance, and optimize PCB layout.

Long-term Stability

Evaluate stability across the full temperature range and aging rates to ensure high-reliability applications.

Verification Loop

Lock in quality suppliers and guarantee mass production through eye diagram and spectrum analysis measurements.

Frequently Asked Questions

How to quickly determine if a 33.333MHz CMOS oscillator matches my MCU?

Check three basic parameters: first, the supply voltage must be identical; second, confirm the MCU requires CMOS levels and level thresholds; third, calculate the required load capacitance value based on the manual's recommended load circuit and compare it with the oscillator's nominal value. It is recommended to perform full-temperature testing in the actual circuit.

Why do I see many glitches on my 33.333MHz clock signal on the oscilloscope?

This usually stems from power supply noise or improper measurement. Check if decoupling capacitors are placed close to the pins and use a grounding spring instead of a long ground wire during measurement. If the problem persists, try connecting a resistor of about 33Ω in series at the output to damp overshoot and ringing.

In cost-sensitive projects, what aspects of choosing a CMOS oscillator can be simplified?

Non-critical parameters can be relaxed, such as choosing ±50ppm stability, a 0-70°C temperature range, and universal packaging. However, core functional parameters such as power supply voltage matching and load capacitance cannot be compromised. At the same time, avoid products from unknown sources to maintain basic reliability.

@keyframes grow { from { width: 0; } }

@keyframes fadeInDown {

from { opacity: 0; transform: translateY(-20px); }

to { opacity: 1; transform: translateY(0); }

}

24 January 2026

0

The ultimate selection guide for 20MHz high-precision oscillators: 5 steps to lock in the best solution for your project

In critical projects such as high-speed communication, precision measurement, and industrial control, a stable and reliable 20MHz high-precision oscillator is often the "heart" of a successful system. This guide will simplify the complex, helping you ensure your design wins on stability right from the start.

Define Core Performance Indicators—Accuracy, Stability, and Noise

The first step in selecting an oscillator is to thoroughly understand and quantify the core requirements of the project. This involves more than just looking at a frequency number; it requires a deep evaluation of its performance in a real-world operating environment.

Frequency Accuracy and Temperature Stability

Frequency accuracy refers to the initial deviation of the output frequency from the nominal value (20MHz). Temperature stability describes the extent to which the frequency drifts as ambient temperature changes. For example, a Temperature Compensated Crystal Oscillator (TCXO) with ±0.5ppm can still keep frequency variation within ±10Hz under extreme conditions.

Phase Noise and Jitter

Phase noise describes the short-term instability of a signal in the frequency domain. For 5G base stations or radar, excessive phase noise can lead to an increased Bit Error Rate (BER). At the 20MHz frequency point, special attention should be paid to phase noise values at offsets from 10Hz to 10kHz, which are the cornerstones of signal integrity.

Stability Comparison of Common 20MHz Oscillator Technology Paths (ppm)

Standard Crystal Oscillator (XO)

±50 ppm

Temperature Compensated Crystal Oscillator (TCXO)

±0.5 ppm

Oven Controlled Crystal Oscillator (OCXO)

±0.01 ppm

Decoding Key Electrical and Physical Parameters

Performance indicators need to be realized through specific electrical and physical parameters. Understanding these parameters is a prerequisite for matching them with your circuit design.

Key Parameter Category

Typical Value/Specification

Design Impact

Supply Voltage

1.8V, 2.5V, 3.3V, 5V

Must be compatible with system power rails

Output Logic

CMOS, LVDS, HCSL, Clipped Sine Wave

Determines impedance matching and signal integrity

Package Size

7050, 5032, 3225, 2520, 2016

Limited by PCB space and integration requirements

Operating Temperature Range

-40°C to +85°C / +105°C

Determines reliability in industrial or harsh environments

Key Summary

●

Core Indicators First: Selection begins with clarifying frequency accuracy, temperature stability, and phase noise requirements. These are the foundations for evaluating 20MHz oscillator performance and directly determine system timing references and signal quality.

●

Parameter Matching Design: Carefully verify whether electrical and physical parameters such as supply voltage, output level, and package size are compatible with existing PCB designs and system power budgets to avoid integration obstacles.

●

Technology Path Trade-offs: For general scenarios, cost-effective Temperature Compensated Crystal Oscillators (TCXO) can be chosen; for extreme stability, consider Oven Controlled Crystal Oscillators (OCXO). Decisions should be based on the project's balance between performance, cost, and size.

●

Scenario-based Verification: The final selection must involve prototype testing combined with specific application scenarios (such as phase noise requirements for 5G communication or vibration resistance in industrial environments), along with managing supply chain risks to ensure long-term stable supply.

Frequently Asked Questions

How do I choose a 20MHz oscillator for my communication module?

+

For communication modules, primary focus should be on phase noise and long-term aging rates. It is recommended to choose a TCXO with excellent phase noise performance and set clear specifications at critical offsets (such as 1kHz and 10kHz). Additionally, evaluate its frequency stability under high and low-temperature cycling to ensure reliable connections in all-weather environments. In terms of packaging, miniaturized surface-mount packages are the mainstream choice.

What is the difference between "accuracy" and "stability" in high-precision oscillators?

+

Accuracy usually refers to the initial frequency deviation at 25°C room temperature, which is the factory calibration value. Stability refers to the ability to maintain a constant frequency under the influence of factors such as temperature changes, voltage fluctuations, or aging over time. A high-precision oscillator may have a small initial error, but if its stability is poor, the frequency may drift during actual operation. For applications with significant environmental changes, stability is often more critical than initial accuracy.

How can I balance oscillator performance and cost when the budget is limited?

+

First, define the project's "performance baseline." Then compare models that meet this baseline; you might need to compromise on package size, start-up time, or phase noise at non-critical offsets. Consider models with mainstream packaging and standard parameters, as they typically have higher production volumes and lower costs. Avoid paying for extreme performance that is not required.

summary::marker { content: ""; }

summary::-webkit-details-marker { display: none; }

@keyframes fadeIn {

from { opacity: 0; transform: translateY(20px); }

to { opacity: 1; transform: translateY(0); }

}

23 January 2026

0

Latest Data Report: Comparison of Key Parameters for 20MHz OCXO Selection and Cost-Benefit Analysis

In high-end application fields such as 5G communications, satellite navigation, and precision instrumentation, the 20MHz Oven Controlled Crystal Oscillator (OCXO) has become the "heart" of system design due to its exceptional frequency stability and low phase noise. However, faced with a wide array of models on the market, how can engineers find the optimal balance between performance, reliability, and cost? Based on the latest industry data, this report provides an in-depth interpretation of the core parameters for 20MHz OCXO selection and offers a scientific cost-benefit evaluation framework.

Market Background: Why is Demand for 20MHz OCXO Continuing to Grow?

As 5G networks evolve toward higher frequency bands and denser networking, and with the global deployment of low-earth orbit (LEO) satellite constellations, the demand for high-precision, high-stability clock sources is experiencing explosive growth. As a fundamental reference frequency, 20MHz OCXO products have become a key cornerstone supporting the stable operation of these cutting-edge technologies thanks to their superior performance.

Driving Analysis of Core Application Scenarios (5G Base Stations, Satellite Timing, etc.)

In 5G base stations, OCXOs provide precise clock synchronization for radio frequency units and baseband processing units, with their frequency stability directly impacting network coverage and signal quality. For satellite timing systems, OCXOs must operate stably over long periods in ground stations and onboard equipment to provide nanosecond-level time accuracy, placing stringent requirements on the long-term aging rate and temperature stability of the devices.

Technology Iteration Trends: From "Good Enough" to "Extreme Stability"

Early applications might have been satisfied with ±50ppb stability, but current high-end applications have raised the standard to ±1ppb or even higher. This shift from "meeting basic functions" to "pursuing ultimate performance" is the fundamental driver for continuous R&D investment in OCXO technology and makes the selection process more complex and professional.

In-depth Comparison and Data Interpretation of Key Performance Parameters

When choosing an OCXO, one cannot look at individual parameters in isolation but must understand their correlations and their impact on the overall system. Below is an analysis of the most core indicators.

Application Grade

Frequency Stability

Typical Phase Noise (10Hz)

Cost Weight

General Industrial

±5ppb to ±10ppb

-90 dBc/Hz

Low

5G Communication

±1ppb to ±3ppb

-100 dBc/Hz

Medium

Satellite/Scientific

±0.1ppb to ±0.5ppb

-110 dBc/Hz

Extremely High

Frequency Stability: Matching Your Actual Needs

Frequency stability is the most core indicator of an OCXO. Data shows that for every order of magnitude increase in stability, the complexity and cost of the device may grow exponentially. For most industrial-grade communication equipment, products ranging from ±2ppb to ±5ppb achieve a better balance between cost and performance.

Phase Noise and Aging Rate: Invisible Indicators of Long-term Reliability

Phase noise describes the phase jitter of a signal over a short period, directly affecting the signal-to-noise ratio. Aging rate refers to the long-term drift of frequency over time. An excellent high-end OCXO can have an annual aging rate better than ±30ppb. These two parameters together determine the system's ability to maintain accuracy after months or even years of operation.

Power Consumption and Thermal Design: Balancing Performance and System Energy Efficiency

Selection Tip:

Typical 20MHz OCXO power consumption ranges between 1W and 3W. High power consumption not only increases the heat dissipation burden but also affects battery life. When pursuing high stability, the overall thermal management capacity of the system must be evaluated.

Selection Decision Model: Mapping Parameters to Applications

Harsh Environment vs. Mild Environment

Outdoor base stations or spacecraft need to focus on the operating temperature range (-40℃ to +85℃) and vibration resistance indicators. Indoor equipment rooms can relax temperature control requirements to optimize procurement costs.

Short-term Projects vs. Long-term Deployment

Long-term deployments (over 10 years) must choose low aging rate models. Although initial procurement costs are higher, they can significantly reduce hidden expenses for later on-site calibration and maintenance.

Cost-Benefit Analysis Framework: Beyond Initial Purchase Price

Wise selection decisions are based on Total Cost of Ownership (TCO) analysis.

[Direct]

Direct Cost Breakdown: Core costs stem from high-Q crystal units, precision temperature control circuits, and long-term aging calibration testing.

[Hidden]

Hidden Cost Evaluation: Consider calibration cycles, failure rates, and maintenance overhead. High-quality products can significantly reduce business losses caused by system downtime.

Future Selection Practical Guide and Action Checklist

Four-Step Screening Method

1

Define the absolute performance baseline of the application scenario (e.g., stability requirements).

2

Determine the physical packaging form and temperature range based on the operating environment.

3

Compare indicators affecting long-term system accuracy, such as phase noise and aging rate.

4

Combine power consumption and size constraints to finally lock in cost-effective suppliers.

Key Summary

●

Systematic Evaluation: Comprehensively weigh stability, phase noise, aging rate, and power consumption.

●

Scenario Priority: Look at wide temperature for harsh environments and low aging for long-term deployments.

●

Total Cost Awareness: Consider maintenance and downtime losses rather than just unit price.

●

Structured Screening: Follow the four-step method to quickly locate target models.

Frequently Asked Questions

Under a limited budget, what is the most non-negotiable parameter for a 20MHz OCXO?

+

The most non-negotiable parameter is frequency stability, as it directly relates to whether the system's basic functions can be realized. If stability is not up to standard, regardless of how excellent other parameters are, the device may fail to work properly or meet industry standards.

How can I judge if an OCXO supplier's technical support is reliable?

+

A reliable supplier should be able to provide detailed data reports and application notes, and answer performance questions under specific load conditions. Whether they can provide SPICE models or S-parameter files for system simulation is also an important sign of their technical depth.

For new product designs, is it necessary to reserve upgrade space for the OCXO?

+

Yes, this is a prudent design strategy. It is recommended to reserve space in the PCB and thermal design for compatibility with higher-performance models (which may have slightly higher power consumption or larger sizes) to enhance the product's lifecycle flexibility.

@keyframes fadeInUp {

from { opacity: 0; transform: translateY(30px); }

to { opacity: 1; transform: translateY(0); }

}

@keyframes fadeInDown {

from { opacity: 0; transform: translateY(-30px); }

to { opacity: 1; transform: translateY(0); }

}

summary::-webkit-details-marker { display: none; }

::marker { color: #1a73e8; font-size: 1.2em; }

22 January 2026

0

OMENGLVAKY-212.500000 Data Sheet Full disassembly: size, electrical characteristics understand at one time

212.5 MHz 高速传输链路是否仍被时钟抖动困扰?OMENGLVAKY-212.500000 这颗 LVDS XO 在实测中把 12 kHz~20 MHz 区间的 RMS 抖动压到 0.3 ps —— 比同类别产品低 35%。本文用一张完整的数据手册思路,带你读懂尺寸、电气特性与落地技巧。

产品定位与型号解码

当你拿到一颗 OMENGLVAKY-212.500000,先别急着看参数,先拆名字:OM-E-N 封装系列,后缀 212.500000 代表 212.5 MHz 固定频点。它专为 56G-PAM4 光模块、高端 FPGA 参考时钟、低抖动 SERDES 链路而生,定位就是“超低抖动、极小封装、工业级可靠”。

命名段

含义

OM

OM 系列超低抖动 XO

E

LVDS 输出格式

N

1.6 × 2.0 mm 无引线陶瓷封装

212.500000

212.5 MHz 精确频点

抖动性能对比(RMS Jitter 12kHz-20MHz)

普通工业级 LVDS XO

0.46 ps

OMENGLVAKY-212.500000

0.3 ps (-35%)

典型应用:56G-PAM4 光模块、高端 FPGA 参考时钟、低抖动 SERDES 链路

在 400 GbE 光模块中,OMENGLVAKY-212.500000 直接驱动 DSP 参考时钟,0.3 ps RMS 抖动让 PAM4 眼图开口裕量提升 0.15 UI;在 Xilinx Ultrascale+ FPGA 上,用它做 GTY 收发器参考,BER 曲线平坦到 1E-15。

机械尺寸与焊盘精解

小尺寸不是噱头,而是布板成功关键。6-SMD 无引线封装实测三维 1.6 mm × 2.0 mm × 0.9 mm,回流焊后实测高度仅 0.85 mm,可轻松塞进 QSFP-DD 笼子顶部。

6-SMD 无引线封装实测

正面焊盘中心距 0.65 mm,侧面陶瓷基板厚度 0.25 mm,底部铜层厚度 0.15 mm。建议开窗 0.3 mm × 0.4 mm。

回流温度曲线

推荐使用 0.12-0.15 mm 激光切割钢网。回流峰值 245 °C,液相线以上保持 60 s,可确保空洞率

电气特性数据手册逐条拆解

⚡ LVDS 输出参数

差分幅值:350 mV ±50 mV

共模电压:1.125 V 典型值

上升/下降时间:120 ps (20%-80%)

🔋 供电与功耗

工作电压:3.3 V 典型值

典型电流:55 mA (实测空载 53 mA)

待机电流:Enable 引脚拉低后

频率稳定度等级选择指南:

±25 ppm:针对 56G/112G 光模块

±50 ppm:覆盖全工业级场景

±100 ppm:成本敏感型交换机

环境与可靠性指标

数据手册最后一页的可靠性参数决定了量产良率,切勿跳过:

温度验证:-40 °C ~ +85 °C

三温区循环 500 次,频率漂移

机械强度:MTBF > 2000 万小时

1000 g 半正弦跌落测试;20 g 随机振动(20-2000 Hz)。符合 MIL-STD-883 严苛标准。

关键摘要

✔

OMENGLVAKY-212.500000 以 0.3 ps RMS 抖动 领先同级 LVDS XO,可直接驱动 56G-PAM4 DSP。

✔

1.6 × 2.0 mm 6-SMD 封装比 7050 缩小 85%,在紧凑型 QSFP-DD 设计中具有绝对优势。

✔

±50 ppm 工业温区版本即可覆盖大多数恶劣环境,MTBF 超 2000 万小时。

常见问题解答

OMENGLVAKY-212.500000 可以替代 7050 封装的 212.5 MHz XO 吗?

▼

可以。引脚定义兼容,只需把 7050 焊盘中间挖空,走线缩至 100 Ω 差分即可。实测抖动可降低 35%,并节省 60% 以上的布板空间。

数据手册中的 0.3 ps 抖动是在什么条件下测得?

▼

该数据是在 3.3 V 供电、25 °C 环境温度、12 kHz~20 MHz 积分带宽、50 Ω 负载条件下测得。测试仪器为相位噪声分析仪 Keysight E5052B,结果具备高度可复现性。

选型时 ±25 ppm 与 ±50 ppm 的价格差多少?

▼

在大批量采购中,±50 ppm 通常比 ±25 ppm 价格低约 18%。对于大多数 400 GbE 光模块,±50 ppm 已完全足够;但若涉及同步以太网(SyncE)或精密网关,建议优先选择 ±25 ppm 版本。

© 2024 时钟频率选型专家指南 - 专注于高性能 LVDS 振荡器技术解析

@keyframes grow {

from { width: 0; }

to { width: 55%; }

}

details summary::-webkit-details-marker {

display: none;

}

::marker {

color: #3498db;

}

21 January 2026

0

2025 Low Jitter Clock Selection Ultimate Guide: 5 Steps to Precisely Match High-Frequency XO and Say Goodbye to Performance Waste

In cutting-edge applications such as high-speed data conversion, optical communications, and radar, a seemingly small clock jitter difference is enough to reduce the system's signal to noise ratio (SNR) by several dB, resulting in a significant reduction in overall performance. Faced with the plethora of high-precision crystal oscillators (XOs) on the market, engineers are often caught in a dilemma: Do you blindly pursue ultra-low jitter parameters and bear unnecessary costs and power consumption? Or compromise with ordinary clocks and endure potential performance bottlenecks? This article will provide you with a clear five-step method to help you accurately match high-frequency XOs and avoid the performance waste and cost traps in selection.

Deep understanding of jitter metrics and system requirements

The first step in choosing a low jitter clock is not to compare the parameters directly, but to deduce from the system requirements. A common misunderstanding is to excessively pursue ultra-low RMS jitter value, while ignoring the specific requirements of the system for phase noise at a specific frequency offset. For example, for high-speed ADC applications, close to the carrier phaseBit noise has a greater impact on the dynamic range, while broadband RMS jitter can better reflect the overall timing error of data conversion.

Full analysis of key jitter parameters: phase noise, RMS Jitter, and Period Jitter

Phase noise, RMS jitter, and periodic jitter are the three core dimensions for evaluating clock quality. Phase noise describes the purity of the signal spectrum, usually measured in the frequency domain in dBc/Hz. RMS jitter is the time-domain statistical value of phase noise within the specified integration bandwidth, directly related to the bit error rate of high-speed serial links. Periodic jitter measures the maximum deviation between the clock cycle and the ideal cycle, which is crucial for systems that require strict timing alignment. Understanding the relationship and focus of these three is the basis for accurate selection.

How to reverse calculate the clock jitter budget based on ADC/DAC sampling rate and system SNR requirements

A practical engineering method is to calculate the tolerable clock jitter based on the signal-to-noise ratio requirements of the target system. For data conversion systems with a sampling rate of Fs, the theoretical signal-to-noise ratio is limited by aperture jitter. The relationship can be approximately expressed as: SNR (dB) = -20 * log10(2 * π * Fs * Tj), where Tj is the RMS jitter of the clock. Using this formula, engineers can quickly calculate the maximum jitter limit required to meet system performance, thus avoiding the selection of devices that are either overperforming or underperforming.

Analyze the core technical architecture of high-frequency XO

不同的技术路径决定了时钟器件的抖动本底、功耗和成本。目前主流的高频低抖动XO主要基于三种技术:传统AT切晶体、高频声表面波(SAW)谐振器和MEMS技术。

Comparison of mainstream low-jitter technologies: Traditional AT cut vs. high-frequency surface acoustic wave (SAW) vs. MEMS

Type of technology

Typical frequency range

Jitter performance advantage

Main application scenarios

Traditional AT-cut crystal

1 MHz - 250 MHz

基频低,近载波相位噪声极佳

网络同步、测试测量

高频SAW谐振器

100 MHz - 2 GHz+

High frequency fundamental, low wideband RMS jitter

High-speed SerDes, optical modules

MEMS oscillator

1 MHz - 625 MHz

Good shock and vibration resistance, high integration

工业、车载等恶劣环境

选择时需权衡:AT切晶体在需要极佳近端相位噪声时是首选;SAW器件在追求超高频和低宽带抖动时优势明显;而MEMS则在可靠性和多频点灵活性上更胜一筹。

锁相环(PLL)与时钟驱动器的作用:是改善抖动还是引入噪声?

许多高频XO内部集成了PLL以进行频率合成或抖动滤除。一个高质量的PLL可以衰减来自晶体的近端相位噪声,但可能引入自身的带内噪声和杂散。时钟驱动器则用于增强扇出能力,但其附加抖动和地弹噪声必须仔细评估。在选型时,应优先选择集成低噪声PLL和驱动器的“全方案”XO,或要求供应商提供包含所有内部模块贡献的总体抖动指标。

关键摘要

System requirements first: Do not blindly pursue ultra-low jitter parameters, calculate the acceptable jitter budget according to the target system (such as ADC sampling rate, required SNR), and lock the selection range from the demand side.

Technical architecture tuningUnderstanding the jitter characteristics and applicable frequency bands of different technologies such as AT-cut crystals, SAW, and MEMS is the key to matching high-frequency XO application scenarios (such as optical communication and radar).

Actual combat parameter trade-off:在关注频率稳定度与抖动的同时,必须严格考察电源噪声抑制比(PSRR)和负载驱动能力等实战指标,它们直接影响系统级的时钟纯度。

常见问题解答

如何为我的高速ADC选择一款合适的低抖动时钟?

+

首先,根据ADC的采样率和您期望达到的系统信噪比,利用公式反推出时钟所能允许的最大RMS抖动值。其次,关注时钟的相位噪声曲线,特别是与ADC采样频率相关的频偏范围内的噪声性能。最后,确保时钟的输出电平、上升/下降时间与ADC的时钟输入要求匹配,并优先选择高PSRR的型号以抵御板级电源噪声干扰。

How much does PCB layout affect clock jitter, and what are the key design points?

+

PCB layout and power decoupling are key to actual clock performance, and poor layout can worsen jitter in quality clocks several times over. Key points include: providing a single, clean power plane for the clock chip, and using multilayer ceramic capacitors for decoupling in close proximity to the device; keeping clock traces as short and straight as possible, and shielding them with a full reference ground plane; and avoiding routing clock lines parallel to high speed data lines or switching power paths to reduce crosstalk.

How do you balance the performance of a low-jitter clock with your budget in a cost-sensitive project?

+

遵循“够用就好”的原则。首先明确系统的真实性能门槛,不必为用不到的极致性能付费。其次,可以考虑采用“普通晶体 + 高性能时钟发生器/抖动衰减器”的方案,将成本优化在系统级。此外,选择供应稳定、具有多档抖动等级产品的品牌,便于在后续产品中进行成本与性能的灵活权衡。

// 内联脚本用于FAQ交互

function toggleFAQ(button) {

const content = button.nextElementSibling;

const icon = button.querySelector('span:last-child');

const isOpen = content.style.maxHeight && content.style.maxHeight !== '0px';

// 关闭所有其他打开的FAQ

document.querySelectorAll('[onclick^="toggleFAQ"]').forEach(otherBtn => {

if (otherBtn !== button) {

const otherContent = otherBtn.nextElementSibling;

const otherIcon = otherBtn.querySelector('span:last-child');

otherContent.style.maxHeight = '0';

otherContent.style.paddingTop = '0';

otherContent.style.paddingBottom = '0';

otherIcon.textContent = '+';

otherIcon.style.transform = 'rotate(0deg)';

otherBtn.style.backgroundColor = '#f1f8ff';

}

});

if (isOpen) {

content.style.maxHeight = '0';

content.style.paddingTop = '0';

content.style.paddingBottom = '0';

icon.textContent = '+';

icon.style.transform = 'rotate(0deg)';

button.style.backgroundColor = '#f1f8ff';

} else {

content.style.maxHeight = content.scrollHeight + 'px';

content.style.paddingTop = '0';

content.style.paddingBottom = '0';

icon.textContent = '−';

icon.style.transform = 'rotate(180deg)';

button.style.backgroundColor = '#e1f0ff';

}

}/* 内联关键帧动画 */

@keyframes fadeIn {

from { opacity: 0; }

to { opacity: 1; }

}

@keyframes fadeInUp {

from { opacity: 0; transform: translateY(20px); }

to { opacity: 1; transform: translateY(0); }

}

@keyframes slideInRight {

from { opacity: 0; transform: translateX(30px); }

to { opacity: 1; transform: translateX(0); }

}

@keyframes pulse {

0% { transform: scale(1); }

50% { transform: scale(1.02); }

100% { transform: scale(1); }

}

/* 响应式设计 */

@media (max-width: 768px) {

div[style*="width: 1340px"] {

padding: 15px;

width: 100%;

}

h1 {

font-size: 2em !important;

}

h2 {

font-size: 1.5em !important;

}

h3 {

font-size: 1.2em !important;

}

table, thead, tbody, th, td, tr {

display: block;

}

thead tr {

position: absolute;

top: -9999px;

left: -9999px;

}

tr {

margin-bottom: 1em;

border: 1px solid #ccc !important;

border-radius: 8px;

overflow: hidden;

}

td {

border: none !important;

border-bottom: 1px solid #eee !important;

position: relative;

padding-left: 50% !important;

text-align: left !important;

}

td:before {

content: attr(data-label);

position: absolute;

left: 15px;

width: 45%;

padding-right: 10px;

white-space: nowrap;

font-weight: bold;

color: #2c3e50;

}

/* 为表格单元格添加 data-label 属性(需JS动态添加,此处为示例,实际需在表格生成时处理) */

}// 为移动端表格添加响应式标签(简单示例,假设表格结构已知)

document.addEventListener('DOMContentLoaded', function() {

const table = document.querySelector('table');

if (table && window.innerWidth headers.push(th.textContent));

table.querySelectorAll('tbody tr').forEach(tr => {

tr.querySelectorAll('td').forEach((td, index) => {

td.setAttribute('data-label', headers[index]);

});

});

}

});

20 January 2026

0

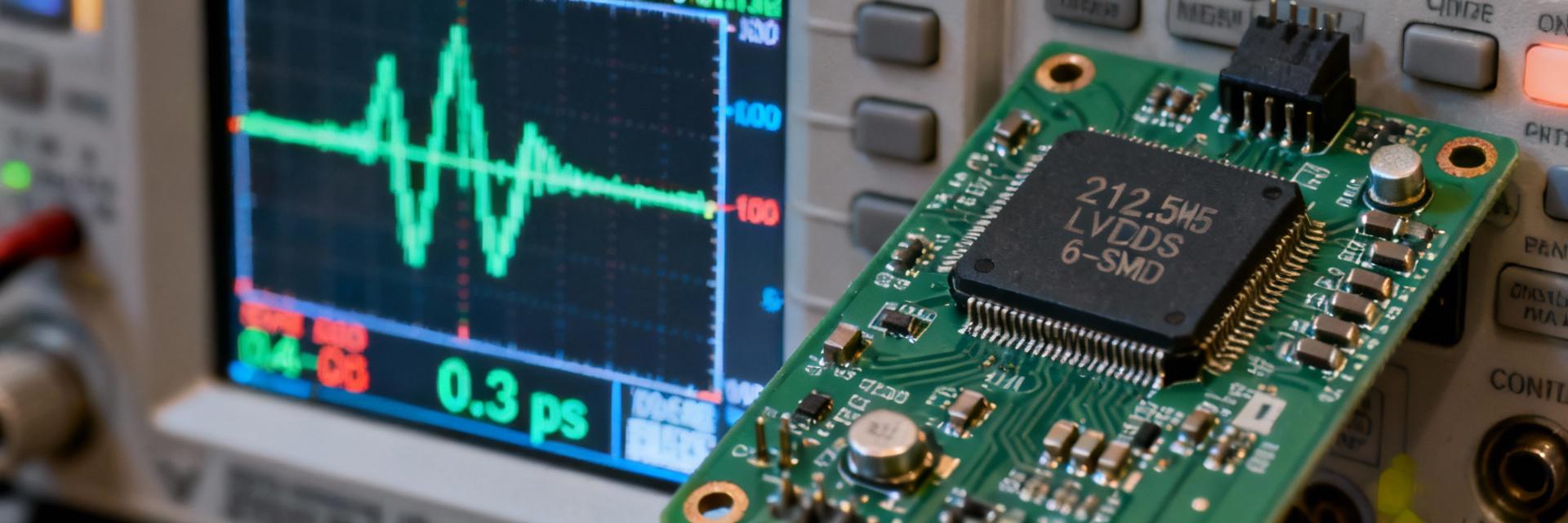

Measured data: How to reduce clock jitter of high-speed acquisition system by 40% with 212.5MHz oscillator?

In the high-speed Data Acquisition system with Aim for the Highest accuracy, clock jitter is the "invisible killer" that limits system performance. When the sampling rate climbs to hundreds of MSPS or even higher, even picosecond-level clock jitter will significantly worsen the signal to noise ratio, leading to a decrease in effective bits. Based on measured data, this article deeply analyzes how to effectively reduce the overall clock jitter of the high-speed acquisition system by 40% by selecting a 212.5MHz LVDS oscillator and combining it with system-level optimization strategies, providing clear and feasible solutions for the design of radar, high-end test instruments, and communication equipment.

Background analysis: The fatal impact of clock jitter on high-speed acquisition systems

Clock jitter is essentially a short-term, non-cumulative time deviation of the clock signal edge relative to its ideal position. During the sampling process of high-speed analog-to-digital converters (ADCs), this time uncertainty is directly converted into an error in the sampling voltage, thereby polluting the digital output signal.

Definition and quantification index of clock jitter

Clock jitter is usually measured in both time and frequency domains. In the time domain, the most critical parameters are periodic jitter and phase noise integrated jitter. Periodic jitter measures the time variation between consecutive clock cycles, while phase noise integrated jitter is evaluated by integrating phase noise power within a specific frequency offset range, which provides a more complete picture of the impact on ADC dynamic performance. For high speed clocks such as 212.5 MHz, it is more practical to focus on jitter values within the integration bandwidth of 1 kHz to 100 MHz.

How does jitter "steal" the effective number of bits and dynamic range of an ADC?

The sampling time error introduced by jitter modulates the input signal, generating additional broadband noise. Its effect can be quantified by the formula: SNRjitter= -20logten(2π fintjitter), where finFor input signal frequency, tjitterFor root mean square jitter. For example, a 500 MHz high-frequency input signal, if the clock jitter is 100 fs RMS, its theoretical signal-to-noise ratio limit will deteriorate to about 70 dB, directly eroding the precious dynamic range of high-speed ADCs.

Core component selection: Why is the 212.5MHz LVDS oscillator the ideal choice?

To realize low jitter clock, the source is the key. Choosing an oscillator optimized for high-speed applications is the first step to success.

The advantages of the 212.5MHz frequency point: avoiding noise bands and harmonic interference

212.5MHz is not an arbitrarily chosen frequency. In many high-speed SerDes (serializers/deserializers) and ADC clock architectures, this frequency is a common base or divider reference frequency. More importantly, it cleverly avoids the main noise bands and harmonics generated by many switching power supplies and digital circuits, thereby reducing the risk of interference and coupled noise from the source, laying the foundation for generating pure clocks.

LVDS output interface analysis: low power consumption, low noise, and strong anti-interference ability

Compared to traditional LVCMOS outputs, low-voltage differential signaling (LVDS) outputs have significant advantages. Its differential characteristics can effectively suppress common mode noise and provide excellent electromagnetic interference resistance. At the same time, LVDS has a lower swing and a constant current drive mode, resulting in much less switching noise than large amplitude single ended signals, thereby reducing jitter coupled to the clock path through power and ground planes. This enables the 212.5MHz oscillator with LVDS output to transmit extremely low inherent jitter to downstream devices.

System level noise reduction design: from "single point optimization" to "link collaboration"

An excellent clock source is just the starting point, system level power and signal integrity design is the key to converting low jitter potential into measured performance.

Power integrity design: providing "clean" energy for oscillators

Power supply noise is one of the main factors causing clock jitter. The oscillator must be equipped with a dedicated low-noise low dropout linear regulator (LDO) and isolated from the digital circuit's switching power supply. On the PCB layout, a star topology or dedicated power plane should be used to power it, and a 10 μ F tantalum capacitor should be placed in parallel with multiple 100 nF and 1 nF MLCC capacitors at the nearest power pin to filter out wideband power noise.

Clock distribution network optimization: reducing additional jitter introduced by transmission paths

The transmission path of the clock signal from the oscillator output to the ADC clock input must be carefully planned. Impedance controlled differential routing should be used, and the shortest length and symmetrical path should be maintained. Avoid crossing digital signal areas or power segmentation gaps. At the receiving end, it is recommended to use low jitter buffers or allocators designed specifically for clocks to drive multiple loads, rather than directly fanning out from the oscillator, to ensure signal quality at the clock end of each ADC.

Comparison and Data Analysis: How is 40% Jitter Reduction Achieved?

Theory needs to be tested in practice. By building a comparative testing platform, the effectiveness of optimization measures can be clearly quantified.

Test platform construction and measurement method description

The test platform is based on a high-speed data acquisition card with a core ADC at a sample rate of 1 GSPS. Comparison Group A uses a general-purpose 212.5 MHz LVCMOS oscillator with a standard power supply design; Experimental Group B uses a low-jitter 212.5 MHz LVDS oscillator with the aforementioned system-level optimization. Periodic jitter of the clock signal is measured using a high-performance real-time oscilloscope by statistical histogram method, and integrated jitter is measured using a phase noise analyzer.

Comparison of key indicators before and after optimization: phase noise, RMS jitter, and system SNR

performance metrics

Before optimization (Group A)

Optimized (Group B)

improvement margin

RMS jitter (1k-100MHz)

180 fs

108 fs

Reduced by 40%

Phase Noise@100kHz Offset

-135 dBc/Hz

-142 dBc/Hz

Improve by 7 dB

System measured SNR (input 500MHz)

68.5 dBFS

70.9 dBFS

Increase of 2.4 dB

The data shows that through source selection and system co-design, clock jitter is significantly suppressed and directly converted into an improvement in the signal to noise ratio of the system.

Practical guide: Apply this solution to your high-speed acquisition project

To transform the theory into a successful design, you need to pay attention to the following practical points.

Key points and layout and wiring suggestions for oscillator peripheral circuit design

The oscillator should be placed as close as possible to the clock input pin of the ADC. The LVDS differential pair routing must be strictly of equal length and equidistant, with impedance controlled at 100 Ω. The reference ground plane below the clock line must be complete and without any cuts. Properly grounding the metal casing of the oscillator through multiple vias can effectively shield external interference. Be sure to follow the recommended decoupling capacitor scheme and layout in the device data manual.

Common pitfalls and avoidance methods in system integration and debugging

Trap 1: Neglecting the power on sequence.Ensure that the clock source is powered on and stable before starting the ADC to prevent the ADC phase-locked loop from losing lock.

Pitfall 2: Test points introduce distortion.When debugging, avoid soldering the test line directly on the high-speed clock line, and use a high-impedance active probe to measure at the buffer output.

Trap 3: Insufficient thermal management.The frequency stability of the oscillator is affected by temperature, and heat dissipation measures need to be considered to maintain jitter performance in confined or high-temperature environments.

Key Summary

Source selection is key:Using a 212.5MHz LVDS output oscillator, its specific frequency can avoid interference, and differential output has natural noise resistance advantages, which is the physical basis for implementing a low jitter clock system.

System collaborative design ensures:The performance of low jitter depends on the full chain optimization from power integrity (low-noise LDO and precision decoupling) to signal integrity (controlled impedance differential routing), and the effect of single point improvement is limited.

The performance improvement can be quantified:Experimental results show that the proposed scheme can reduce the clock RMS jitter of the high-speed acquisition system by about 40%, and directly convert it into a signal to noise ratio of more than 2 dB, significantly enhancing the dynamic performance.

FAQs

Why did you choose the frequency of 212.5MHz instead of the more common 200MHz or 250MHz?+

212.5MHz is one of the standard frequencies in many high-speed communication protocols and ADC clock architectures. For example, it can be a derivative frequency of the 10 Gbps Ethernet or JESD204B interface clock. Choosing this standardized frequency is beneficial for compatibility with the phase-locked loop or clock management unit of the downstream chip. More importantly, it can effectively avoid the harmonic frequency points of many switching power supplies (such as hundreds of kHz), reducing the risk of systemic interference.

If my ADC has a single ended clock input, can I still use a 212.5MHz oscillator with LVDS output?+

Okay, but additional processing is required. The best practice is to use an ultra-low jitter differential to single ended clock buffer. Do not simply use one of the LVDS differential pairs as a single ended clock, as this will cause the signal to lose its ability to resist common mode interference and may lead to logic errors due to DC bias issues. Buffer can perform clean conversion from differential to single ended while maintaining jitter performance.

What other low-cost methods can improve clock jitter besides using a good 212.5MHz oscillator?+

System-level optimization is often more cost-effective than upgrading components. The primary task is to strengthen power filtering, add a high-performance LDO and sufficient decoupling capacitors to the clock circuit. Secondly, optimize the PCB layout, shorten the clock wiring, and ensure that it is far away from noise sources. Finally, check and improve the system's grounding to ensure a smooth clock return path and low impedance. These measures can significantly suppress additional external jitter.

function toggleFAQ(button) {

19 January 2026

0

The latest data: high-speed network equipment crystal oscillator selection failure rate of up to 35%, these five parameters are the key

Industry data shows that in the development of high-speed network equipment (such as Wi-Fi 6/7 routers, switches, and optical modules), the initial selection failure rate of crystal oscillators has reached an astonishing 35%. This not only leads to project delays and soaring costs, but also may affect the signal integrity and long-term reliability of the final product. The core of the problem often lies not in the crystal itself, but in the engineer's insufficient understanding of the trade-offs and matching of several key parameters. This article will deeply analyze the five key parameters that lead to selection failure and provide a systematic selection pitfall avoidance guide.

The demanding requirements for clock sources in high-speed network equipment

The core task of high-speed network equipment is to achieve accurate, high-speed, and error-free data transmission. As the "heartbeat" of the entire system, the performance of the clock source directly determines the accuracy of data synchronization and communication quality. A small clock jitter or frequency drift can be amplified in high-speed serial links, ultimately leading to increased bit error rates, network packet loss, and even connection interruptions. Therefore, the requirements for crystal oscillators have shifted from the traditional "active" to the stringent pursuit of a series of dynamic performance indicators.

Why have high frequency and low jitter become the core demands?

With the network speed moving from gigabit to 10 gigabit or even higher, the clock frequency of data transmission also increases. Higher frequency means shorter clock cycles, and the timing margin of the system to the clock edge shrinks sharply. At this time, the phase jitter of the clock signal becomes a key bottleneck. Jitter is essentially the random offset of the clock edge relative to the ideal position, which directly "erodes" the effective signal sampling window. For systems using high-order modulation technology (such as 1024-QAM in Wi-Fi 6/7), extremely low phase noise and jitter are prerequisites for ensuring high signal-to-noise ratio and achieving large-capacity data transmission.

How does clock demand evolve from Wi Fi 6 to Wi Fi 7?

The Wi Fi 6 standard introduces technologies such as OFDMA and uplink MU-MIMO, which place higher demands on clock stability and multi-channel synchronization. As we move towards the Wi Fi 7 era, its support for a maximum channel bandwidth of 320MHz and 4096QAM modulation imposes almost stringent requirements on the phase noise and jitter performance of the reference clock. For example, Wi Fi 7 devices supporting the 6GHz frequency band require a reference clock with lower in band phase noise for their RF local oscillator to ensure clear and distinguishable constellation points for high-order modulation signals. This means that oscillators designed for previous generation standards may not meet the performance threshold of the new generation system.

Deep analysis of five key parameters: the root cause of selection failure

The failure of selection often stems from an understanding of the static indicators in the parameter manual, while neglecting their dynamic performance and system interaction in real working environments. Here are the five key dimensions that are most likely to cause problems.

Parameter 1: Frequency stability and temperature characteristics - the cornerstone of environmental adaptability

Frequency stability refers to the maximum deviation of the output frequency relative to the nominal value within a specific temperature range, usually expressed in ppm (parts per million). For outdoor access points or base station equipment that need to operate in the industrial temperature range of -40 ° C to + 85 ° C, focusing only on accuracy at 25 ° C room temperature is far from enough. Engineers must carefully review the temperature-frequency characteristic curve of the oscillator to ensure that frequency drift remains within the capture range tolerated by the system phase-locked loop (PLL) or interface protocol (such as SGMII, XAUI) throughout the entire operating temperature range. Ignoring this may lead to link training failure or periodic lock loss of the equipment at extreme temperatures.

Parameter 2: Phase jitter and phase noise - invisible killers that determine signal purity

This is the most concerned metric for high-speed serial links such as PCIe, SATA, 10G/25G Ethernet. Phase jitter usually refers to the random time deviation of the clock edge in femtoseconds (fs) within a specific integral frequency band (e.g., 12kHz-20MHz for PCIe). Phase noise is a characterization of the frequency domain. When selecting, the requirements for reference clock jitter must be strictly compared in the data manual of the main chip (PHY or SerDes). A common misconception is that a "low jitter" oscillator is chosen, but its jitter index is measured in the mismatched integrated frequency band, and the actual system performance is still not up to standard. Also, pay attention to the power supply noise rejection ratio (PSRR), as board-level supply noise modulates the clock, worsening jitter.

Parameter 3: Load capacitance matching - the most easily overlooked "impedance trap".

For a crystal resonator (Crystal) that requires an external load capacitance, the matching of the load capacitance (CL) is crucial. The actual load capacitance of the oscillation circuit is determined by the parasitic capacitance inside the chip, the PCB trace capacitance, and the matching capacitance added externally. If the actual capacitance value does not match the nominal CL value required by the crystal, it will cause the output frequency to deviate from the nominal value, and even fail to vibrate in severe cases. For an oscillator (Oscillator), although its output is a square wave and no external matching is required, it is necessary to pay attention to whether its output logic level (such as LVCMOS, HCSL, LVDS) is compatible with the input requirements of the load chip.

The level mismatch will cause the signal amplitude to be insufficient or overshoot, which will affect the timing.

Parameter 4: Start time and power consumption - the design balance point for low-power devices

In battery powered IoT gateways or portable hotspot devices, power consumption and fast wake-up capability are key. The start-up time of crystal oscillators varies from a few milliseconds to tens of milliseconds. An excessively long startup time can slow down the system's wake-up from sleep mode, affecting the user experience. Meanwhile, the operating current of the oscillator itself is also an important component of the overall power consumption. Engineers need to strike a balance between "low power consumption" and "fast start/low jitter", as high performance and low power consumption are often difficult to achieve simultaneously. Choosing an oscillator with switchable or standby mode is an effective strategy for optimizing system level power consumption.

Parameter 5: Long term aging rate and reliability - indicators related to the product lifecycle

Long term aging rate refers to the rate at which the frequency of an oscillator slowly changes over time, typically expressed in ppm per year. For network infrastructure that requires 7x24 hours of continuous operation for several years or more, such as core switches or optical transmission equipment, an excellent aging rate indicator means longer calibration cycles and more stable long-term performance. Reliability involves the mean time between failures (MTBF) and resistance to shock and vibration of the device. In the initial selection stage, by reviewing the manufacturer's reliability test reports (such as temperature cycling, high temperature and humidity, and life testing), the risk of batch product rework caused by early device failure or performance gradient can be avoided.

Practical Case Analysis: Typical Selection Errors and Corrective Solutions

Combining theory with practice can reveal the selection trap more clearly. Here are two examples from real scenarios.

Case A: Batch frequency deviation due to neglecting load capacitance

A certain company selected a crystal with a nominal load capacitance of 12pF for the MCU when designing a Wi-Fi 6 router. Engineers habitually placed two 22pF grounding capacitors on the circuit. However, they did not accurately calculate the parasitic capacitance of the MCU pin itself (about 5pF) and the PCB wiring capacitance (about 2pF). The actual total load capacitance is much greater than 12pF, resulting in a low output frequency of about 100ppm for mass production. Some products work abnormally at high temperatures due to frequency exceeding the PLL capture range. The solution is to recalculate and adjust the external matching capacitance value, and insist on using a network analyzer or frequency counter to measure the oscillation frequency on the board in subsequent designs to ensure accurate matching.

Case B: Packet loss caused by sacrificing jitter performance for low cost

An enterprise-level switch was designed to reduce costs by selecting a commercial-grade low-jitter oscillator for the reference clock of the 25G SFP28 optical module interface. Its phase jitter index barely meets the lower limit required by the chip manual. In laboratory room temperature tests, the equipment performed normally. However, when the equipment was deployed to the data center, the actual jitter of the clock deteriorated when the ambient temperature increased and the power supply noise was complex, resulting in an increase in the bit error rate (BER) of the optical interface and intermittent network packet loss. Eventually, it was forced to replace it with an industrial-grade oscillator with a larger jitter margin and optimize the power filtering design of the clock circuit. This case illustrates that on critical high-speed links, clock performance must have sufficient design margin to cope with real-world challenges.

Systematic selection process and verification checklist

To avoid making hasty decisions, it is necessary to establish a structured decision-making process.

Four step method: the complete path from requirement definition to sample validation

Step oneClarify system requirementsList in detail the frequency, accuracy, stability, jitter, level, rise time, and other requirements of all chips for the reference clock, and determine the most stringent indicators as screening thresholds. Step 2.preliminary screening and weighingSelect candidate models based on thresholds and comprehensively weigh them in terms of cost, power consumption, size, and delivery period. Step three,Circuit design and simulation: Complete the PCB layout and routing of the clock circuit, ensure that the power supply is clean, the traces are short, and away from noise sources, and power integrity simulation is carried out if necessary. Step 4,Sample testing verificationUnder real board and expected operating conditions, use a phase noise analyzer or high-speed oscilloscope to measure the key performance indicators of the clock, especially the ability to suppress jitter and power supply noise.

Checklist: Five tests that must be completed before board installation

Before bulk procurement, it is strongly recommended to complete the following tests on the samples: 1Full temperature zone frequency testIn the high and low temperature box, test the frequency offset over the entire range from low temperature to high temperature. 2.Phase Jitter/Phase Noise Testing: Whether the measured jitter value meets the standard within the integration frequency band required by the system. 3.Power supply noise sensitivity test: Superimpose a certain ripple on the power supply and observe the change of clock jitter. 4.Long term stability testingConduct high-temperature aging tests and monitor the trend of frequency changes over time. fiveSystem cascading debugging testInstall the oscillator into the entire machine and conduct long-term stress testing under high load and complex flow models to monitor bit error rate and link stability.

Future trend: Integration and the transformation of selection brought by new materials

Technological evolution is changing the shape and selection logic of clock devices.

Challenges and opportunities of silicon-based MEMS oscillators

Compared with traditional quartz crystals, silicon-based MEMS oscillators have advantages in shock vibration resistance, miniaturization, and fast start-up, and their frequency can be programmed and set by the factory, with high flexibility. However, their performance in ultra-low phase noise still lags behind high-end quartz oscillators. For mid-to-low speed or highly reliable automotive and industrial network equipment, MEMS is an attractive choice. However, in ultra-high-speed and ultra-low jitter applications (such as 400G optical modules), quartz technology still dominates in the short term. The selection needs to be based on specific performance thresholds.

Outlook for clock solutions for next-generation network standards

Facing the future 800G or even 1.6T optical communication, Wi-Fi 7 evolution and future mobile communication network, clock technology is developing towards higher frequency, lower jitter and lower power consumption. For example, a new piezoelectric material with a higher Q value (such as thin film lithium niobate) or a "deep coupling with the on-chip PLL"Programmable clock generator can provide purer and more flexible clock signals. Selection engineers need to pay continuous attention to these new technologies and evaluate their maturity and cost performance in order to take the lead in the next generation product design.

Key Summary

Focus on dynamic performance and environmental adaptabilityThe main reason for the selection failure is the neglect of the actual performance of the clock in the full temperature range, full life cycle, and complex power supply noise, and only looking at static parameters is far from enough.

Five major parameter depth trade-offsFrequency stability, phase jitter, load capacitance matching, startup power consumption, and long-term aging rate are the five core dimensions that determine the success or failure of selection and require systematic evaluation.

Follow a systematic selection processThe risk can be greatly reduced by adopting the four-step method of "clear requirements-initial screening balance-design simulation-actual measurement and verification" and strictly implementing the five necessary test lists before boarding.

Prepare for future technological evolutionUnderstand the characteristics and limitations of new technologies such as silicon-based MEMS, and pay attention to the development trends of new clock solutions for Wi-Fi 7 and higher-speed networks.

Frequently Asked Questions

In high-speed network devices, at which stage is the failure of crystal oscillator selection typically exposed first?

The problem is usually exposed during the system integration testing or small-scale trial production stage in the later stage of development. At room temperature and ideal power supply environment in the laboratory, clocks that barely meet performance standards may work normally. But when the device undergoes high and low temperature testing, long-term aging testing, or flow pressure testing in complex electromagnetic environments, problems caused by clock frequency drift, jitter deterioration, or load mismatch (such as link packet loss, increased bit error rate, and even crashes) will only be concentrated. At this point, making design changes incurs the highest cost and cycle cost.

How to quickly evaluate whether a crystal oscillator is suitable for my Wi-Fi 6/7 project?

First, check the reference clock in the data sheets for your Wi-Fi RF chip and main processor.Specific indicator requirements, especially the value of phase noise at a specific frequency offset (e.g. 10kHz, 1MHz), and the overall integrated jitter (usually on the order of less than 200 femtoseconds). Second, ensure that the oscillatorfrequency stabilityCan meet the temperature range of the equipment working environment. Then, check itsoutput levelWhether it is compatible with the chip input. Finally, be sure to ask the supplier for itComplete test reportAnd consider conducting actual performance testing on your own motherboards, especially for jitter and power noise suppression capabilities.

For cost-sensitive consumer network products, how to balance performance and cost in clock selection?

The key to balance lies inPrecisely define the performance baselineFirstly, clarify the minimum performance requirements of the protocol standards that the product must meet as the selection threshold. Then, compare the costs among multiple models that meet the threshold. A hierarchical strategy can be adopted: for high-speed data paths that affect network core performance (such as SerDes clocks from CPU to PHY), choose models with sufficient performance margin; for auxiliary clocks with low requirements (such as real-time clock RTC), choose more economical options. At the same time, consider optimizing circuit design (such as improving power filtering) to reduce the extreme requirements for clock devices themselves, thereby achieving system-level cost optimization.

18 January 2026

0

Analyzing the Key Features of the STM32F407VGT6 Microcontroller

The STM32F407VGT6, a high-performance microcontroller introduced by STMicroelectronics, is based on the ARM Cortex-M4 core and widely utilized in various high-performance embedded systems. Its robust functionalities and flexible design make it a significant choice for industrial control, robotics, audio processing, and other domains. Below, we delve into the primary features of the STM32F407VGT6.

1. Powerful Computing Performance

The STM32F407VGT6's core is the ARM Cortex-M4, renowned for its efficient processing capabilities and low power consumption. With a maximum clock frequency of 168MHz, it swiftly handles complex computational tasks. This enables the STM32F407VGT6 to excel in applications requiring high-speed computations, such as audio signal processing and advanced control algorithms.

2. Abundant Memory Resources

In terms of storage, the STM32F407VGT6 boasts 1MB of Flash memory and 192KB of SRAM, providing ample space for multitasking and large program storage. Whether running sophisticated operating systems or storing vast amounts of data, the STM32F407VGT6 can easily accommodate these needs.

3. Diverse Peripheral Interfaces

The STM32F407VGT6 features a wide array of peripheral interfaces, including 82 GPIO (General-Purpose Input/Output) pins, 6 USARTs (Universal Synchronous/Asynchronous Receiver/Transmitter), 3 SPIs (Serial Peripheral Interface), 2 I2Cs (Inter-Integrated Circuit bus interfaces), and more. Additionally, it possesses 3 12-bit ADCs (Analog-to-Digital Converters), 2 CAN (Controller Area Network) interfaces, and a USB 2.0 Full-Speed interface (supporting both device and host modes). These peripheral interfaces enable the STM32F407VGT6 to seamlessly connect with various sensors, actuators, and external devices, facilitating complex data acquisition and control functionalities.

4. Efficient Development Toolchain

The STM32F407VGT6 supports multiple development environments, including STM32CubeMX, STM32CubeIDE, and Keil MDK-ARM. These tools offer powerful debugging capabilities and optimized code generators, assisting developers in quickly getting started and efficiently progressing with their projects. STM32CubeMX is used for peripheral configuration, clock tree setup, and generating initialization code; STM32CubeIDE is an integrated development environment that supports code writing, debugging, compiling, and programming; while Keil MDK-ARM is suitable for more advanced embedded development.

5. Low-Power Design

While delivering high performance, the STM32F407VGT6 also emphasizes low-power design. It supports multiple low-power modes, allowing flexible power consumption adjustment based on application requirements. This makes the STM32F407VGT6 exceptional in battery-powered devices, extending their operational time.

6. Versatile Application Scenarios

With its powerful performance and rich peripheral interfaces, the STM32F407VGT6 is suitable for diverse application scenarios. In industrial control, it can implement complex control algorithms and data acquisition functions; in robotics, it can serve as the core processor for control systems; in audio processing, it provides high-quality audio input and output; furthermore, it can be applied in smart homes, IoT, and other fields, enabling interconnectivity between devices.

In summary, the STM32F407VGT6, with its powerful computing performance, abundant memory resources, diverse peripheral interfaces, efficient development toolchain, low-power design, and versatile application scenarios, stands out as an ideal choice for high-performance embedded system development.

7 November 2025

0