-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

Latest data for 2025: Comprehensive report on the pass rate, cost, and cycle of IEC 60529 IP certification for domestic products

2025 Latest Data: Panoramic Report on Domestic IEC 60529 IP Certification Pass Rates, Costs, and Cycles

From January to June 2025, 8,742 electronic products, lamps, and outdoor devices nationwide were submitted for IEC 60529 IP rating certification, with a final pass rate of 82.3%, a year-on-year increase of 5.7%. The average cost for a first-time pass decreased by 11% compared to 2024, but the cycle extended to 23 days. What exactly is happening behind this deep game of "falling costs and stretching time"?

H Overview of the Domestic IP Certification Market Background

Driven by the dual forces of "Dual Carbon" goals and the outdoor economy, the IEC 60529 standard has shifted from optional to mandatory. It is expected that by the end of 2025, the market size will exceed 4.2 billion RMB, maintaining an annual growth rate of over 18%.

Key Connection Points between IEC 60529 and GB/T 4208 Standards

The two standards are 100% aligned in terms of testing conditions and determination thresholds; differences only exist in report templates and regulatory filing processes. Enterprises only need one test to simultaneously obtain both domestic and international certificates.

Newly Added Mandatory Scenarios and Regulatory Dynamics in 2025

Starting from July, all lighting fixtures connected to the public lighting network must reach at least IP65; e-commerce platforms have also simultaneously launched "IP Rating Whitelist" automatic interception mechanisms, where uncertified products are directly delisted.

D 2025 Pass Rate Panorama: Digital Breakdown and Category Differences

Segmented data shows that IP certification pass rates are not evenly distributed but present a U-shaped curve that is "high in the middle and low at both ends."

TOP 10 Category First-pass Rate Rankings (IP54→IP69K)

| Category | First-pass Rate Visualization | Main Selling Points |

|---|---|---|

| LED Street Light |

92%

|

Mature structure, standardized sealing process |

| Charging Pile |

89%

|

Uses integrated die-cast aluminum housing |

| Portable Power Station |

87%

|

Silicone sealing ring + nano-coating double insurance |

| Smart Sensor |

84%

|

Ultrasonic welded housing |

| Power Tool |

78%

|

Oil-sealed bearings used with O-rings |

| Underwater Camera |

65%

|

Complex lens pressure-bearing structure |

| Industrial Tablet |

63%

|

Difficult to balance heat dissipation and sealing |

| High-end Headphones |

58%

|

Acoustic chamber openings lead to high risk |

| Drone |

54%

|

Lightweight materials easily deformed |

| Electric Toothbrush |

48%

|

Frequent water ingress through button gaps |

Failure Case Analysis: 3 High-Frequency Failure Modes

- ● Housing Joint Leakage (41%): Often caused by uneven screw torque or sealant aging leading to uneven stress distribution.

- ● Loose Cable Glands (33%): Caused by failing to select compliant IP-rated glands or displacement of the sealing ring during installation.

- ● Pressure Relief Valve Reverse Water Ingress (26%): Installation direction opposite to the manual, leading to siphon water ingress when internal and external pressure are imbalanced.

C Cost Map: Testing Agencies, Cities, and Package Differences

Breaking down certification costs, you will find that "hidden costs" are the key to determining the budget.

Beijing National Laboratory

Full IP65: 7,800–9,500 RMB

Includes: Expedited channel, professional rectification guidance

Shanghai Foreign-invested Lab

IP67 Package: 10,200 RMB

Bonus: Two free re-testing opportunities

Shenzhen Private Laboratory

IP68 Deep Water Tightness: 13,500 RMB

Feature: Flexible pay-per-test, suitable for R&D phase

How to Effectively Control Costs: Strategic Recommendations

Doing "housing air-tightness pre-check" in advance can reduce the failure rate from 18% to 6%, saving 1,200–2,000 RMB in re-testing fees per model; if 3 or more models are submitted at once, mainstream agencies typically offer a quarterly agreement discount of 8–12%.

T Timeline Breakdown: The 23-Day Flow from Sample Submission to Certification

On the surface it is 23 days, but in fact only 9 days are truly used for laboratory environment testing; the remaining time is mainly consumed by procedural steps.

Popular lab schedules are already full until late August

80% of rectifications only require changing sealing rings or applying glue

Time has been shortened by 50% since the launch of electronic signatures

Acceleration Suggestions:

Choosing a laboratory with both CNAS and CMA qualifications can simultaneously start dustproof and waterproof dual-station testing, compressing the overall cycle to 14 days; the expedited fee is about 30% of the basic fee.

Success Case: 11-Day Express Clearance Experience

A certain IP67 portable power station product shortened its cycle by 52% through the following strategies.

Pre-emptive Structural Design

Through front-end 3D printing of prototypes, 2 rounds of air-tightness and drop pre-checks were completed in advance, ensuring no stress concentration points on the housing in extreme environments.

Data Reuse Techniques

Pre-check data from the same lab can be directly imported into the formal testing system, avoiding secondary filing and repeated setup, saving 2–3 days.

A Action List: 2025 H2 Schedule and Self-Check

| Node | Recommended Action | Buffer Reserved |

|---|---|---|

| Before July 15 | Complete structural design freeze (Seal-off) | 3 Days |

| Before August 10 | Internal air-tightness pre-check of the first batch of samples | 2 Days |

| Before September 5 | Formal submission (to avoid National Day holiday queues) | 5 Days |

Internal Team Self-Check List: 15 Core Details

Covers sealing groove width, screw tightening torque, pressure relief valve installation angle, etc. Please ensure full comparison before submission to increase the first-pass rate by 6–8%.

Key Summary: 2025 IEC 60529 Indicators at a Glance

- Pass Rate 82.3% LED street lights and charging pile categories performed most robustly.

- Cost 7.8k–13.5k Quarterly bundling or pre-checking can save another 10–15% in costs.

- Avg. 23-Day Cycle Using expedited and parallel testing can shorten the cycle to as little as 11 days.

Frequently Asked Questions: IEC 60529 IP Certification

- The latest data: high-speed network equipment crystal oscillator selection failure rate of up to 35%, these five parameters are the key

- Measured data: How to reduce clock jitter of high-speed acquisition system by 40% with 212.5MHz oscillator?

- 2025 Low Jitter Clock Selection Ultimate Guide: 5 Steps to Precisely Match High-Frequency XO and Say Goodbye to Performance Waste

- Latest Data Report: Comparison of Key Parameters for 20MHz OCXO Selection and Cost-Benefit Analysis

- The ultimate selection guide for 20MHz high-precision oscillators: 5 steps to lock in the best solution for your project

- How to accurately match the 33.333MHz CMOS crystal oscillator for your project? Five-step pit avoidance guide

- From principle to practice: How to accurately select and match a 312.5MHz LVDS oscillator for your high-speed communication system?

- NJECAEJHNY-20.000000 OCXO failure Big data: high and low temperature cycle loss accounts for 47%

- 10 minutes to complete the selection of Taiyi ON-K series high-frequency crystal oscillators: Engineer's practical step-by-step guide

- OMENGLVAKY-212.500000 Data Sheet Full disassembly: size, electrical characteristics understand at one time

-

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP -

MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP

MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP -

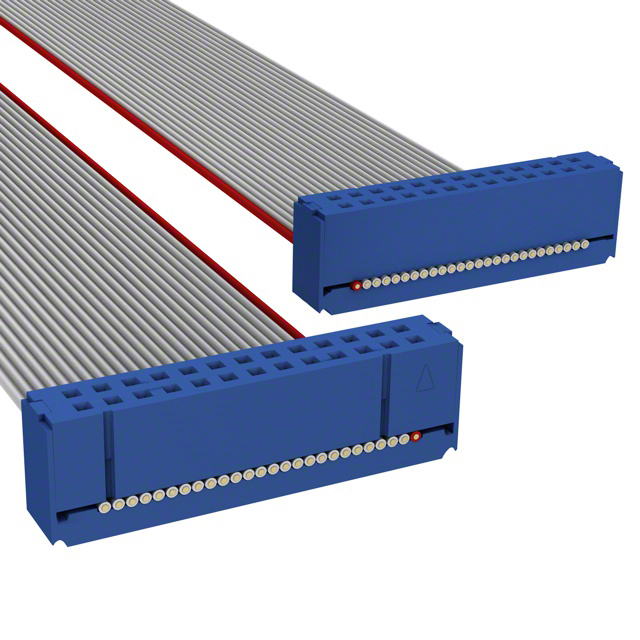

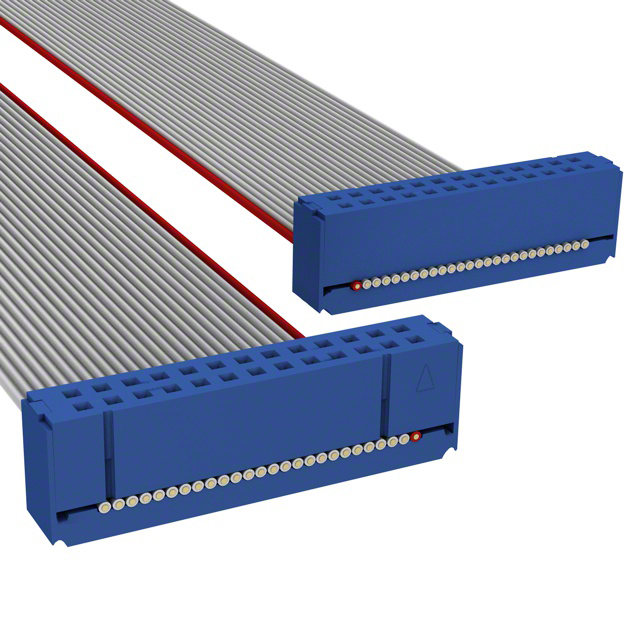

C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

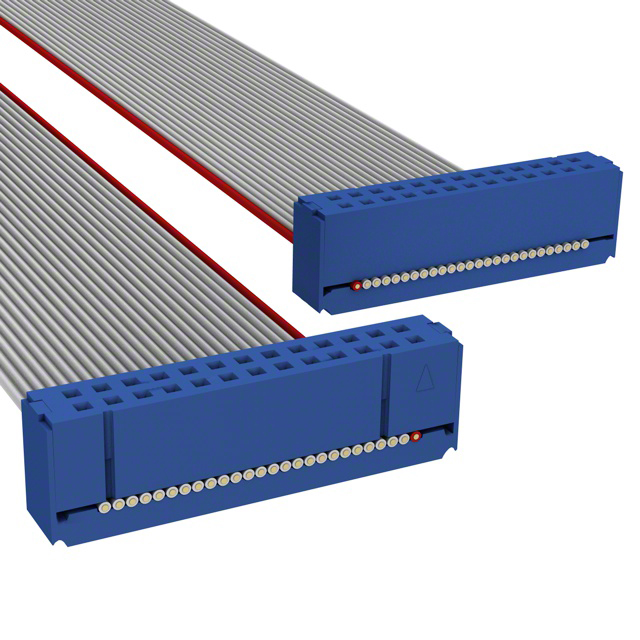

C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T

C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T -

C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

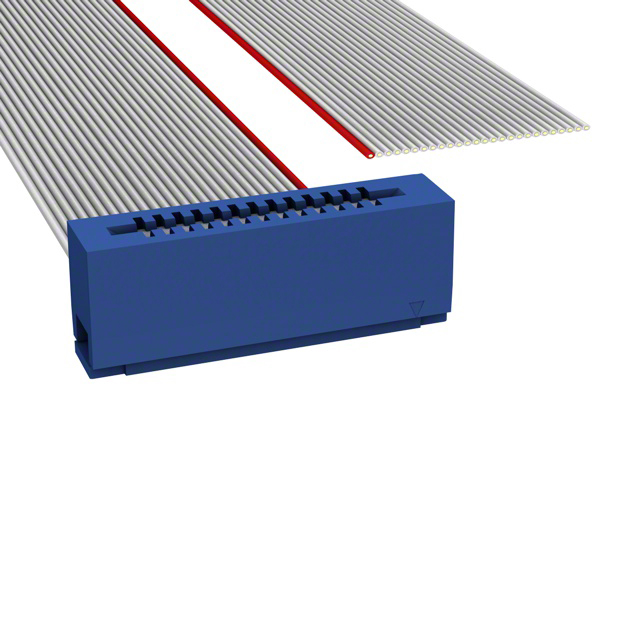

C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X

C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X -

S6008LWickmann / LittelfuseSCR 600V 8A TO220

S6008LWickmann / LittelfuseSCR 600V 8A TO220 -

CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL

CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL -

ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL

ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL