Measured data: How to reduce clock jitter of high-speed acquisition system by 40% with 212.5MHz oscillator?

2026-01-19 11:15:49

0

In the high-speed Data Acquisition system with Aim for the Highest accuracy, clock jitter is the "invisible killer" that limits system performance. When the sampling rate climbs to hundreds of MSPS or even higher, even picosecond-level clock jitter will significantly worsen the signal to noise ratio, leading to a decrease in effective bits. Based on measured data, this article deeply analyzes how to effectively reduce the overall clock jitter of the high-speed acquisition system by 40% by selecting a 212.5MHz LVDS oscillator and combining it with system-level optimization strategies, providing clear and feasible solutions for the design of radar, high-end test instruments, and communication equipment.

Background analysis: The fatal impact of clock jitter on high-speed acquisition systems

Clock jitter is essentially a short-term, non-cumulative time deviation of the clock signal edge relative to its ideal position. During the sampling process of high-speed analog-to-digital converters (ADCs), this time uncertainty is directly converted into an error in the sampling voltage, thereby polluting the digital output signal.

Definition and quantification index of clock jitter

Clock jitter is usually measured in both time and frequency domains. In the time domain, the most critical parameters are periodic jitter and phase noise integrated jitter. Periodic jitter measures the time variation between consecutive clock cycles, while phase noise integrated jitter is evaluated by integrating phase noise power within a specific frequency offset range, which provides a more complete picture of the impact on ADC dynamic performance. For high speed clocks such as 212.5 MHz, it is more practical to focus on jitter values within the integration bandwidth of 1 kHz to 100 MHz.

How does jitter "steal" the effective number of bits and dynamic range of an ADC?

The sampling time error introduced by jitter modulates the input signal, generating additional broadband noise. Its effect can be quantified by the formula: SNRjitter= -20logten(2π fintjitter), where finFor input signal frequency, tjitterFor root mean square jitter. For example, a 500 MHz high-frequency input signal, if the clock jitter is 100 fs RMS, its theoretical signal-to-noise ratio limit will deteriorate to about 70 dB, directly eroding the precious dynamic range of high-speed ADCs.

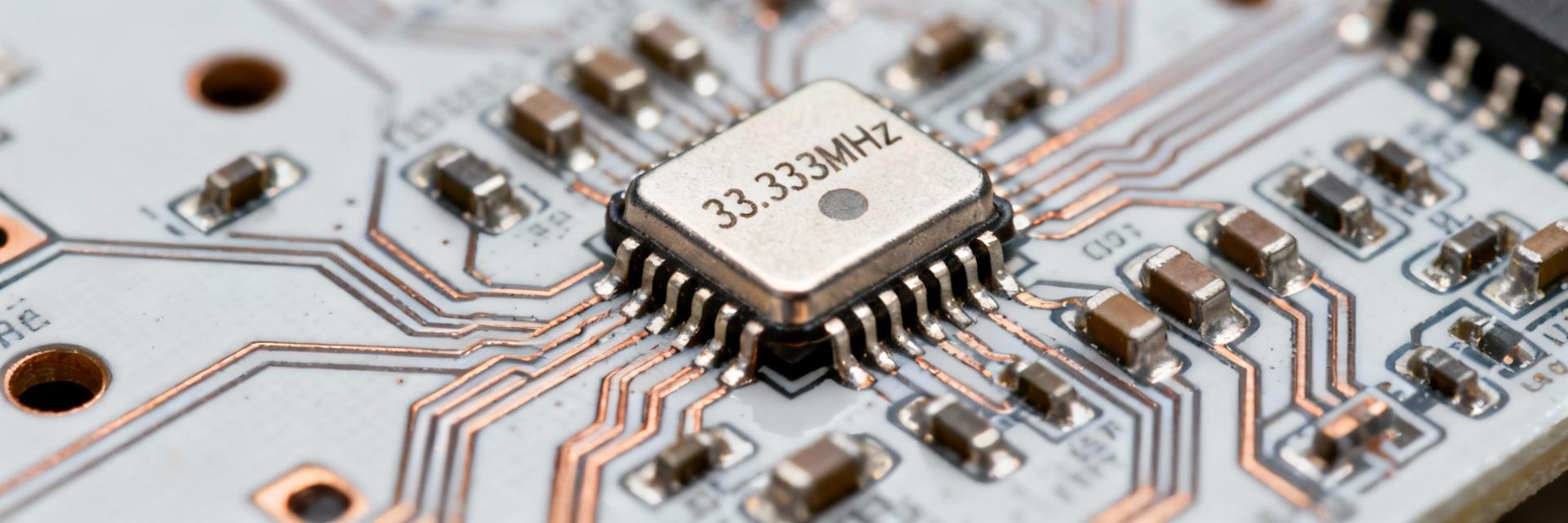

Core component selection: Why is the 212.5MHz LVDS oscillator the ideal choice?

To realize low jitter clock, the source is the key. Choosing an oscillator optimized for high-speed applications is the first step to success.

The advantages of the 212.5MHz frequency point: avoiding noise bands and harmonic interference

212.5MHz is not an arbitrarily chosen frequency. In many high-speed SerDes (serializers/deserializers) and ADC clock architectures, this frequency is a common base or divider reference frequency. More importantly, it cleverly avoids the main noise bands and harmonics generated by many switching power supplies and digital circuits, thereby reducing the risk of interference and coupled noise from the source, laying the foundation for generating pure clocks.

LVDS output interface analysis: low power consumption, low noise, and strong anti-interference ability

Compared to traditional LVCMOS outputs, low-voltage differential signaling (LVDS) outputs have significant advantages. Its differential characteristics can effectively suppress common mode noise and provide excellent electromagnetic interference resistance. At the same time, LVDS has a lower swing and a constant current drive mode, resulting in much less switching noise than large amplitude single ended signals, thereby reducing jitter coupled to the clock path through power and ground planes. This enables the 212.5MHz oscillator with LVDS output to transmit extremely low inherent jitter to downstream devices.

System level noise reduction design: from "single point optimization" to "link collaboration"

An excellent clock source is just the starting point, system level power and signal integrity design is the key to converting low jitter potential into measured performance.

Power integrity design: providing "clean" energy for oscillators

Power supply noise is one of the main factors causing clock jitter. The oscillator must be equipped with a dedicated low-noise low dropout linear regulator (LDO) and isolated from the digital circuit's switching power supply. On the PCB layout, a star topology or dedicated power plane should be used to power it, and a 10 μ F tantalum capacitor should be placed in parallel with multiple 100 nF and 1 nF MLCC capacitors at the nearest power pin to filter out wideband power noise.

Clock distribution network optimization: reducing additional jitter introduced by transmission paths

The transmission path of the clock signal from the oscillator output to the ADC clock input must be carefully planned. Impedance controlled differential routing should be used, and the shortest length and symmetrical path should be maintained. Avoid crossing digital signal areas or power segmentation gaps. At the receiving end, it is recommended to use low jitter buffers or allocators designed specifically for clocks to drive multiple loads, rather than directly fanning out from the oscillator, to ensure signal quality at the clock end of each ADC.

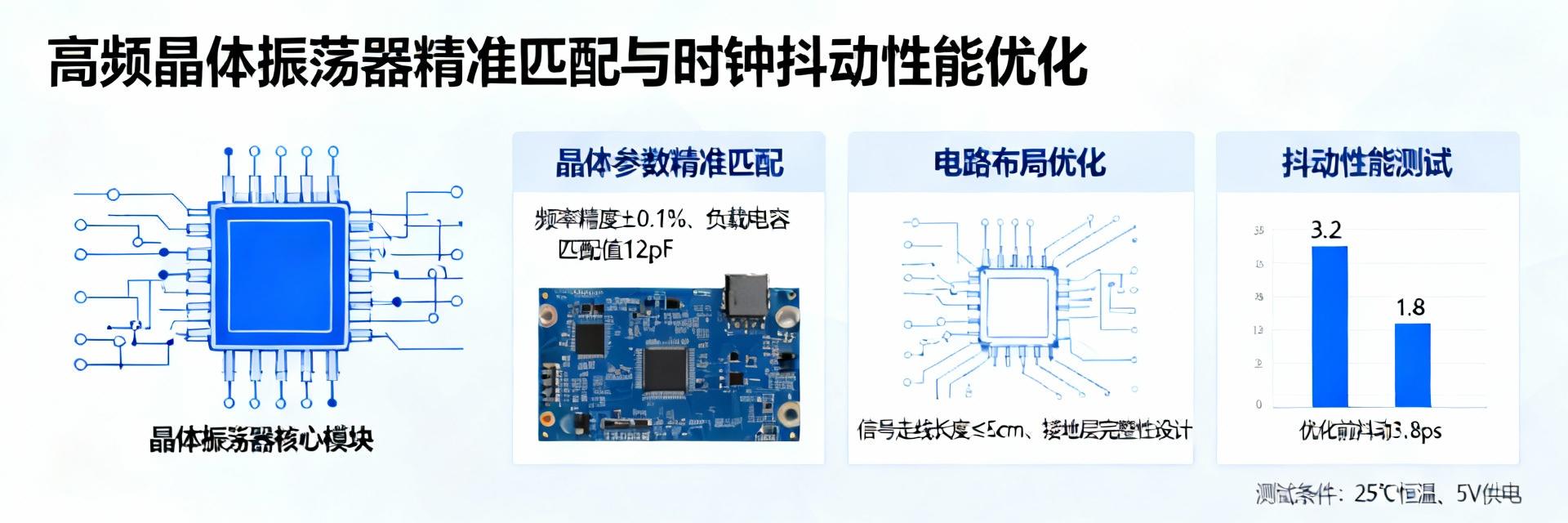

Comparison and Data Analysis: How is 40% Jitter Reduction Achieved?

Theory needs to be tested in practice. By building a comparative testing platform, the effectiveness of optimization measures can be clearly quantified.

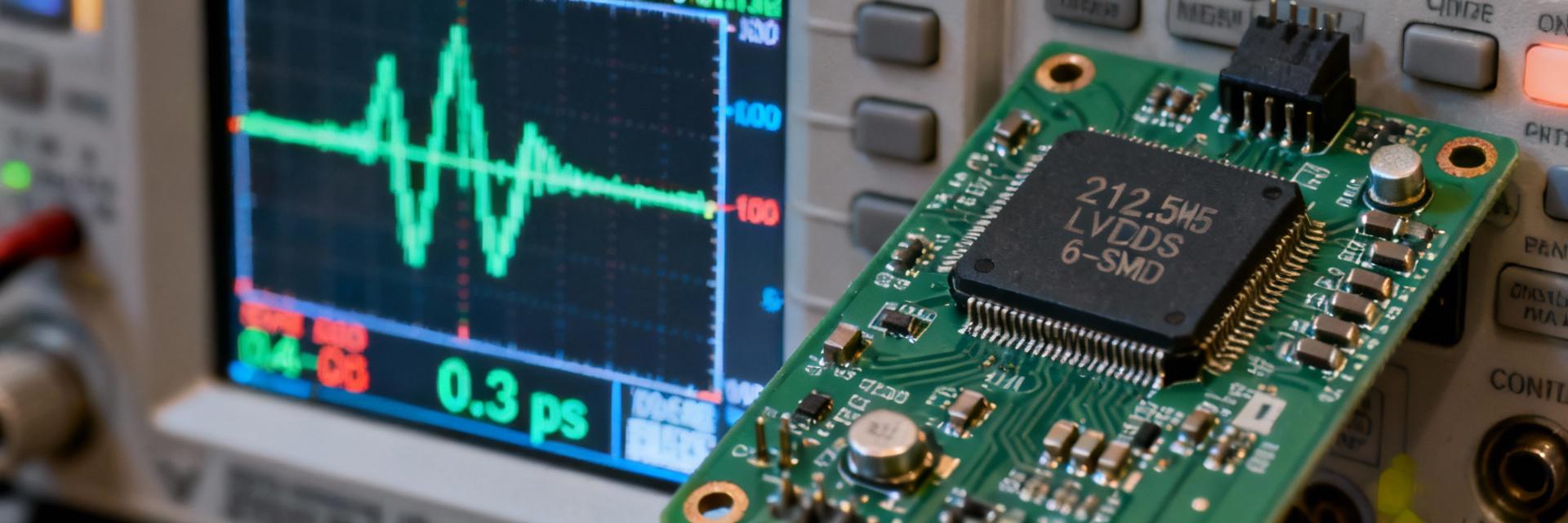

Test platform construction and measurement method description

The test platform is based on a high-speed data acquisition card with a core ADC at a sample rate of 1 GSPS. Comparison Group A uses a general-purpose 212.5 MHz LVCMOS oscillator with a standard power supply design; Experimental Group B uses a low-jitter 212.5 MHz LVDS oscillator with the aforementioned system-level optimization. Periodic jitter of the clock signal is measured using a high-performance real-time oscilloscope by statistical histogram method, and integrated jitter is measured using a phase noise analyzer.

Comparison of key indicators before and after optimization: phase noise, RMS jitter, and system SNR

performance metrics

Before optimization (Group A)

Optimized (Group B)

improvement margin

RMS jitter (1k-100MHz)

180 fs

108 fs

Reduced by 40%

Phase Noise@100kHz Offset

-135 dBc/Hz

-142 dBc/Hz

Improve by 7 dB

System measured SNR (input 500MHz)

68.5 dBFS

70.9 dBFS

Increase of 2.4 dB

The data shows that through source selection and system co-design, clock jitter is significantly suppressed and directly converted into an improvement in the signal to noise ratio of the system.

Practical guide: Apply this solution to your high-speed acquisition project

To transform the theory into a successful design, you need to pay attention to the following practical points.

Key points and layout and wiring suggestions for oscillator peripheral circuit design

The oscillator should be placed as close as possible to the clock input pin of the ADC. The LVDS differential pair routing must be strictly of equal length and equidistant, with impedance controlled at 100 Ω. The reference ground plane below the clock line must be complete and without any cuts. Properly grounding the metal casing of the oscillator through multiple vias can effectively shield external interference. Be sure to follow the recommended decoupling capacitor scheme and layout in the device data manual.

Common pitfalls and avoidance methods in system integration and debugging

Trap 1: Neglecting the power on sequence.Ensure that the clock source is powered on and stable before starting the ADC to prevent the ADC phase-locked loop from losing lock.

Pitfall 2: Test points introduce distortion.When debugging, avoid soldering the test line directly on the high-speed clock line, and use a high-impedance active probe to measure at the buffer output.

Trap 3: Insufficient thermal management.The frequency stability of the oscillator is affected by temperature, and heat dissipation measures need to be considered to maintain jitter performance in confined or high-temperature environments.

Key Summary

Source selection is key:Using a 212.5MHz LVDS output oscillator, its specific frequency can avoid interference, and differential output has natural noise resistance advantages, which is the physical basis for implementing a low jitter clock system.

System collaborative design ensures:The performance of low jitter depends on the full chain optimization from power integrity (low-noise LDO and precision decoupling) to signal integrity (controlled impedance differential routing), and the effect of single point improvement is limited.

The performance improvement can be quantified:Experimental results show that the proposed scheme can reduce the clock RMS jitter of the high-speed acquisition system by about 40%, and directly convert it into a signal to noise ratio of more than 2 dB, significantly enhancing the dynamic performance.

FAQs

Why did you choose the frequency of 212.5MHz instead of the more common 200MHz or 250MHz?+

212.5MHz is one of the standard frequencies in many high-speed communication protocols and ADC clock architectures. For example, it can be a derivative frequency of the 10 Gbps Ethernet or JESD204B interface clock. Choosing this standardized frequency is beneficial for compatibility with the phase-locked loop or clock management unit of the downstream chip. More importantly, it can effectively avoid the harmonic frequency points of many switching power supplies (such as hundreds of kHz), reducing the risk of systemic interference.

If my ADC has a single ended clock input, can I still use a 212.5MHz oscillator with LVDS output?+

Okay, but additional processing is required. The best practice is to use an ultra-low jitter differential to single ended clock buffer. Do not simply use one of the LVDS differential pairs as a single ended clock, as this will cause the signal to lose its ability to resist common mode interference and may lead to logic errors due to DC bias issues. Buffer can perform clean conversion from differential to single ended while maintaining jitter performance.

What other low-cost methods can improve clock jitter besides using a good 212.5MHz oscillator?+

System-level optimization is often more cost-effective than upgrading components. The primary task is to strengthen power filtering, add a high-performance LDO and sufficient decoupling capacitors to the clock circuit. Secondly, optimize the PCB layout, shorten the clock wiring, and ensure that it is far away from noise sources. Finally, check and improve the system's grounding to ensure a smooth clock return path and low impedance. These measures can significantly suppress additional external jitter.

function toggleFAQ(button) {

READ MORE