Declassified Top Secret Archives: How did 17 US soldiers disappear over Armenia when a C-130 reconnaissance plane was shot down in 1958?

2026-02-05 11:01:10

0

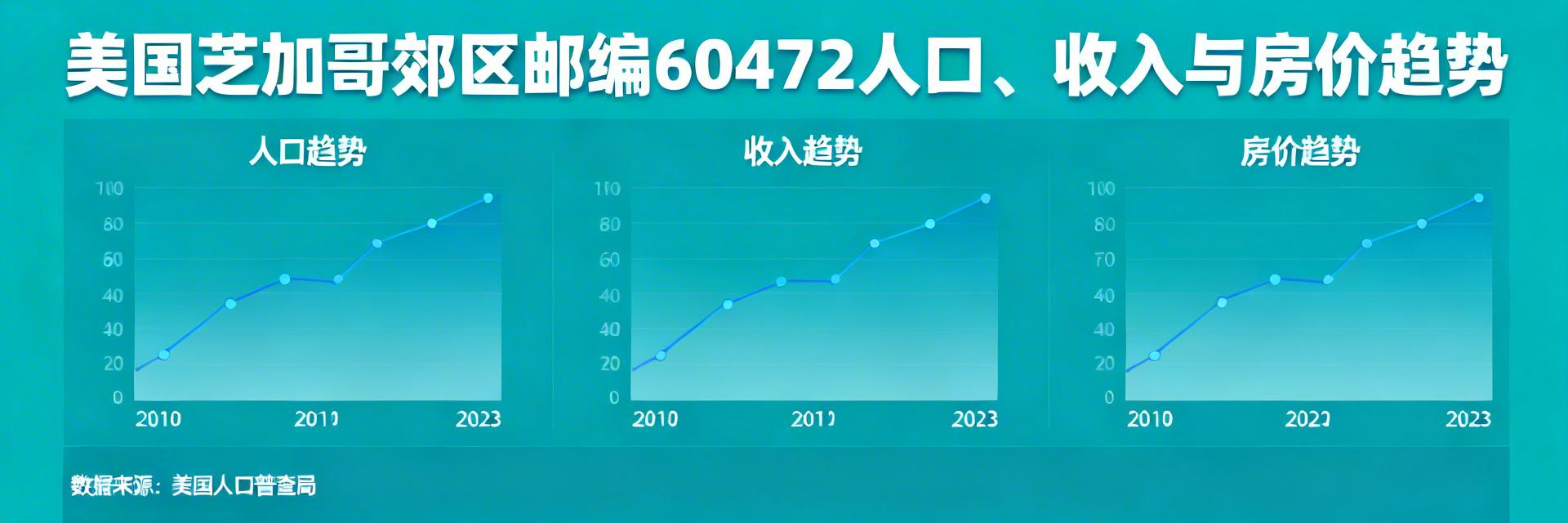

Cold War Declassified Files Publication Date: 2023 Update Category: Military History / Electronic Reconnaissance On September 2, 1958, a U.S. C-130 transport aircraft was shot down over the Armenian Soviet Socialist Republic, and all 17 U.S. personnel on board went missing. This incident was quickly covered up, and relevant files were classified as top secret. It was not until the declassification of some documents in recent years that this most mysterious aerial tragedy of the Cold War gradually came to light. Overview of Reconnaissance Mission Risks During the Cold War Total Cross-border Reconnaissance Thousands Aircraft Destruction/Fatalities Very Few * Data compiled based on the latest declassified Strategic Air Command (SAC) annual summary reports High-altitude Gambit Under the Iron Curtain: Event Background and Mission Nature Image: Schematic of the modified electronic reconnaissance version of the C-130 transport aircraft (Codename: Flight 60528) In the late 1950s, the Cold War between the United States and the Soviet Union reached a fever pitch. Following the Soviet breakthroughs in long-range bomber and missile technology, the U.S. demand for first-hand intelligence on radar deployment and air defense capabilities along its borders became extremely urgent. To this end, the U.S. military planned a series of top-secret missions codenamed "Frontier Reconnaissance," the core of which was to use modified transport aircraft, disguised as "straying" into airspace, to test and collect signals from the Soviet air defense early warning system. These missions were high-risk but were considered to have irreplaceable strategic value. Escalation of U.S.-Soviet Confrontation and the "Frontier Reconnaissance" Strategy Declassified documents show that around 1958, U.S. intelligence agencies knew very little about the military deployments on the southern Soviet border, especially in the Transcaucasian region. This area was a vital gateway for the Soviet Union to the Middle East, holding immense strategic importance. To fill this intelligence gap, the U.S. Air Force Strategic Air Command authorized a series of high-risk, high-reward cross-border flights. These missions were not simple navigational errors but carefully calculated military gambles aimed at mapping the Soviet air defenses. The Special Mission of "Flight 60528": Transport Aircraft or Reconnaissance Platform? The shot-down C-130 had the internal military mission codename "Flight 60528." Although its public identity was a "routine transport aircraft" taking off from Incirlik Air Base in Turkey, fragments of declassified operational orders indicate it was assigned a special electronic reconnaissance mission. This aircraft was likely equipped with the most advanced signals intelligence equipment of the time, used to intercept and record the frequency bands, pulse characteristics, and reaction times of Soviet ground radars. Its flight path was intentionally close to the Soviet airspace boundary, showing a clear "probing" intent to accumulate data for potential future strategic bombing or reconnaissance operations. Intrusion into the Forbidden Zone: Reconstruction of the C-130 Shoot-down Process According to limited information released by the Soviet Union after the fact and later declassified U.S. radar tracking records, the incident occurred in the afternoon local time. After taking off from Turkey, the C-130 flew along the Turkey-Soviet border, and its track subsequently showed it gradually deviating from the planned route, penetrating dozens of kilometers into Armenian airspace. Navigational Error or Intentional Probing? Analysis of the Boundary Crossing Causes Regarding the cause of the boundary crossing, two mainstream interpretations still exist. Officially, the U.S. initially insisted it was a "stray" caused by bad weather and navigational equipment failure. However, many military historians and analysts, based on the declassified nature of the mission, believe it was more likely a planned "brinkmanship" operation aimed at testing the reaction speed and identification capabilities of the Soviet border air defense system. The terrain of the intrusion area chosen by the aircraft was complex, which theoretically favored low-altitude penetration but also made it easier to be trapped by radar blind spots, leading the pilots to misjudge that they had already flown away from the sensitive airspace. The Fatal Attack by MiG-17s: Four Minutes from Warning to Fire Soviet air defense forces quickly captured this uninvited guest. The local air defense aviation units immediately scrambled two MiG-17 fighters for interception. According to the Soviet pilots' post-war reports, they had attempted to issue warnings to the C-130 through international common channels and by rocking their wings, requesting it to follow them for landing. However, the C-130 did not comply and instead attempted to turn and flee. After warnings failed, the MiG-17 fighters, upon instruction from the ground command post, opened fire around 3:00 PM local time. The C-130's right engine and wing root were hit, and it subsequently spiraled out of control and crashed in the Armenian mountains. Core Information Dimensions Declassified Details Mission Aircraft Type Lockheed C-130A-II (Electronic Signals Intelligence Modified Version) Incident Location Airspace over the Armenian Soviet Socialist Republic, USSR Interception Forces 2 Soviet MiG-17 Fighters Crew Count 17 (including 6 crew members and 11 electronic reconnaissance specialists) The Missing 17: Search and Rescue, Cover-up, and Diplomatic Turmoil After the aircraft crashed, Soviet ground forces quickly arrived at the scene. It is said that the crash site was in a remote mountainous area, the scene was tragic, and no survivors were found. The Soviet side maintained strict control over the site and recovered the aircraft wreckage and the victims' remains. Soviet On-site Handling and U.S. Intelligence Silence After the incident, the Soviet government lodged a formal diplomatic protest with the United States, accusing its military aircraft of violating airspace. The U.S. government maintained an unusual silence for the first few days and did not immediately acknowledge the disappearance of the aircraft or its crew. Internal declassified cables show that high-level U.S. officials were urgently assessing the situation, trying to confirm the fate of the personnel through secret channels while simultaneously striving to avoid making this sensitive espionage operation public, which could trigger a more serious diplomatic crisis or even military escalation. The Long Wait for Families and Vague Official Rhetoric For the families of the 17 crew members, the days that followed were filled with agony and confusion. Initially, they only received a brief notice that their loved ones were "missing in action." The military provided no details, stalling on questions about whether the plane was shot down or if the personnel were deceased with excuses like "still under investigation" or "involving national security." This information black hole left the families in painful speculation for decades, and it wasn't until the gradual declassification of files that they pieced together the cruel truth of their loved ones' fate. 📌 Key Summary ■ Special Mission Nature: The U.S. C-130 "Flight 60528" shot down in 1958 was not an ordinary transport aircraft, but was performing a top-secret electronic reconnaissance mission targeting Soviet air defense systems, serving as a high-risk component of the Cold War "Frontier Reconnaissance" strategy. ■ Clear Shoot-down Process: The aircraft was intercepted by MiG-17 fighters for intruding into Soviet Armenian airspace and was shot down after warnings failed. Declassified communication records confirm the rapid process from discovery to destruction. ■ Long-term Cover-up and Information Gaps: After the incident, both the U.S. and the Soviet Union, out of consideration for avoiding escalation of the conflict, did not fully disclose the truth. The U.S. government hid the truth from the victims' families, leading to core files being buried for decades, and many key details remain a mystery to this day. Frequently Asked Questions (FAQ) Why did this C-130 aircraft enter Soviet airspace? Expand ▼ The current mainstream view is that this was not a simple navigational error. According to declassified files, the aircraft was performing a top-secret mission codenamed "Frontier Reconnaissance," aimed at probing and collecting air defense radar intelligence along the Soviet border. Its flight path intentionally skirted or briefly crossed the airspace boundary, representing a planned military gamble to acquire electronic signals intelligence for strategic assessment data. Did the Soviet Union attempt to warn or force the aircraft to land at the time? Expand ▼ According to Soviet pilots' post-war reports and some declassified communication records, the intercepting MiG-17 fighters attempted to warn the C-130 via radio calls and international common visual signals (such as rocking wings) and signaled it to follow for landing. However, the C-130 crew, possibly due to the nature of the mission or a misjudgment, did not comply and attempted to turn and flee, ultimately leading to the Soviet aircraft opening fire. After the incident was declassified, was the fate of the 17 U.S. personnel finally confirmed? Expand ▼ Declassification of files confirmed that the aircraft was shot down and all personnel on board perished. However, specific details regarding the handling of the victims' remains or whether they were returned by the Soviet Union are still not clearly recorded in the released documents. Their final whereabouts, along with many core secrets of the mission, may have vanished forever into history with the passing of those involved. This article is compiled based on public information from the National Declassification Center (NDC) and the Cold War Archive.

READ MORE

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP

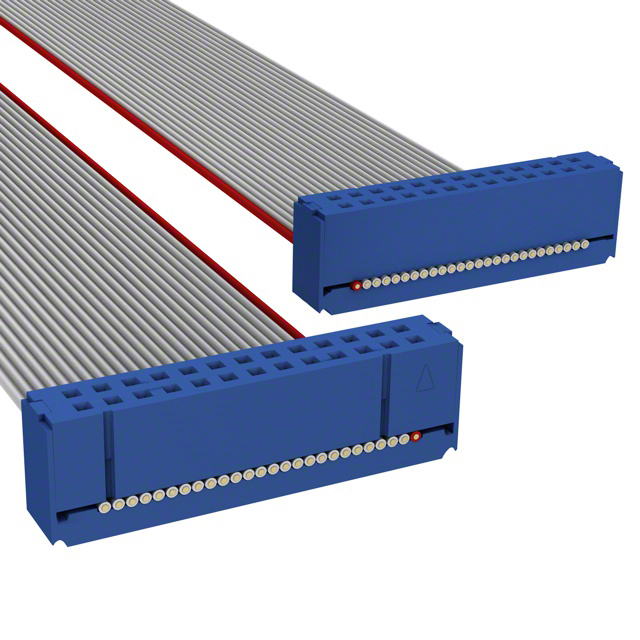

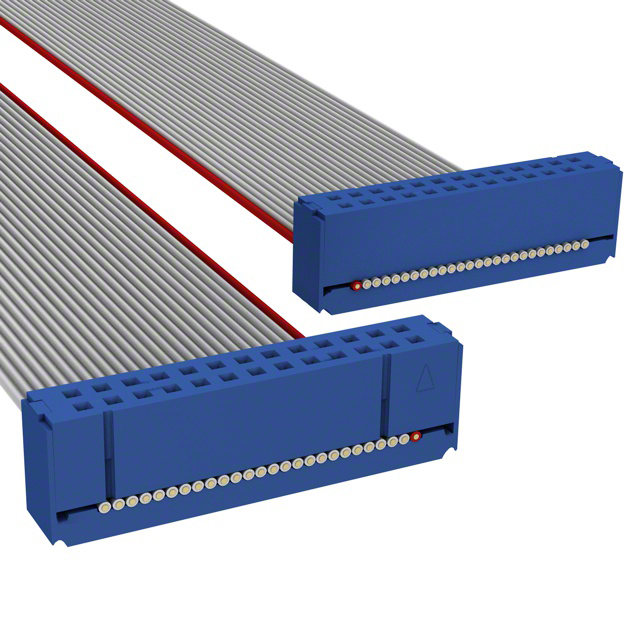

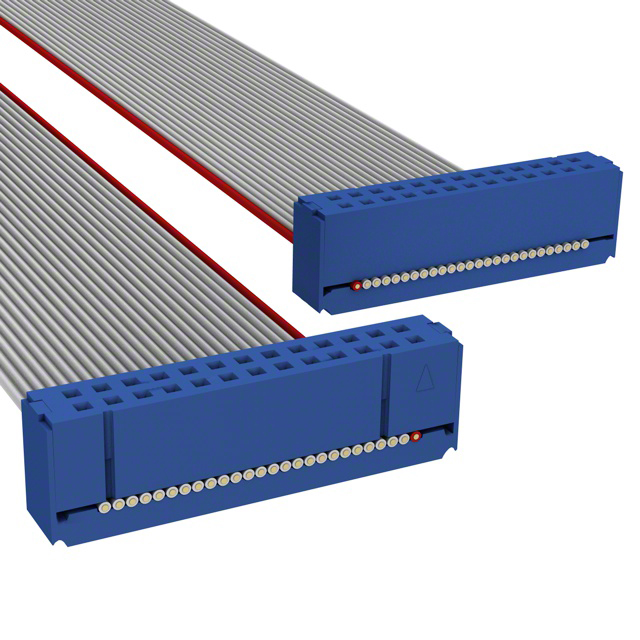

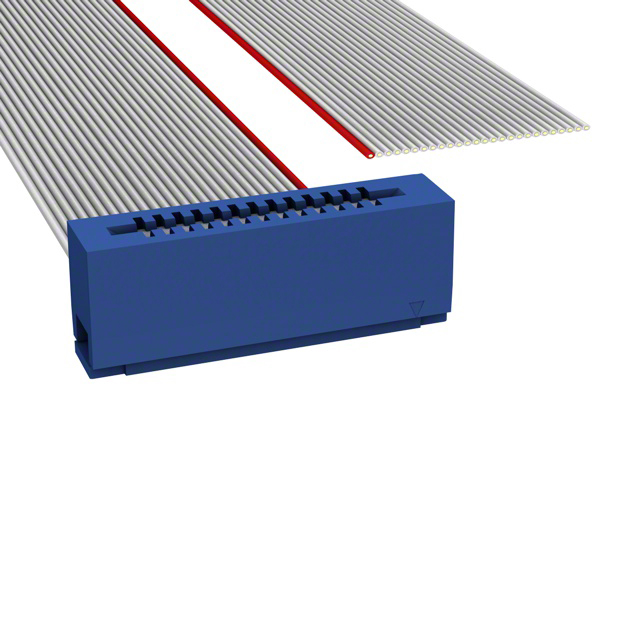

MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T

C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X

C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X S6008LWickmann / LittelfuseSCR 600V 8A TO220

S6008LWickmann / LittelfuseSCR 600V 8A TO220 CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL

CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL

ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL