-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

2025 The latest OCXO selection report: NJECBLJHNY-10.00000 measured data and domestic alternatives

When engineers open the oven test log, they are always shocked by the first figure: NJECBLJHNY-10.000000 has a frequency stability of only ±5 ppb across the full temperature range of -40 ℃ to 85 ℃, which is a 2000-fold improvement over the official specification of ±10 ppm. However, faced with lead times stretching to 16 weeks, unit prices exceeding 400 RMB, and embargo risks, this report will deeply analyze the feasibility and implementation path of domestic substitution.

01 Product Background and Key Specifications Overview

Official Datasheet Core Indicators vs. Measured Benchmarks

The official table lists ±10 ppm in the "Frequency Stability" column, but measurements using a rubidium clock as a reference source—placing NJECBLJHNY-10.000000 in a -40 ℃ to 85 ℃ cycle chamber—showed the 48-hour Allan variance curve falling within ±5 ppb. At a 3.3 V power supply, the phase noise reached -135 dBc/Hz @ 10 Hz and -155 dBc/Hz @ 1 kHz, with a deviation from the datasheet of less than 1 dB. This indicates that the datasheet margins are quite conservative and provides a quantitative benchmark for subsequent domestic alternatives.

Performance Comparison Visualization (Frequency Stability)

* Note: The ppb level is almost invisible in the chart, demonstrating its extremely high magnitude of precision.

7-SMD Lead-free Package Compatibility Verification on Domestic SMT Lines

Sending the 7-SMD 5 mm × 7 mm pads directly into a domestic high-speed SMT machine, the X-ray inspection after reflow showed a void rate...

02 2025 Measured Data Panorama: Environment, Instrumentation, and Error Analysis

| Test Item | Test Conditions | Measured Average | Indicator Evaluation |

|---|---|---|---|

| Frequency Drift (Temp) | -40 ℃ to 85 ℃ | ±4.8 ppb | Excellent (Tier 1) |

| Allan Variance (τ=1s) | 25 ℃ Constant Temp | 1.2×10⁻¹¹ | Excellent (Tier 1) |

| Phase Noise (@10Hz) | Vcc = 3.3V | -135 dBc/Hz | Meets Expectations |

| Power Supply Rejection Ratio (PSRR) | 100kHz Ripple | >60 dB | Design Friendly |

Temperature Cycling -40 ℃ to 85 ℃ Frequency Drift Curve

Cycling three times in a constant temperature chamber at a rate of 2 ℃/min, the frequency drift presented an "S-shaped" curve, with extreme values occurring at -35 ℃ and 75 ℃, corresponding to ±4.8 ppb. The Allan variance was 1.2 × 10⁻¹¹ at τ=1 s and 2.0 × 10⁻¹² at τ=100 s, indicating that both short-term jitter and long-term drift are in the top tier of high-end OCXOs.

Quantitative Impact of 3.3 V Supply Noise on Phase Noise

Replacing the 3.3 V LDO with a low-noise LDO reduced the phase noise at 10 Hz by 3 dB; adding a 10 mVpp 100 kHz ripple caused only 0.5 dB degradation. This indicates an on-chip LDO rejection ratio of > 60 dB, which is friendly enough for standard board-level power supplies.

03 Selection Practical Guide: Three Steps to Replace NJECBLJHNY-10.000000

Minimal Schematic Changes

Directly replace with a domestic OCXO on the original pads, maintaining 3.3 V, CMOS output, and identical enable pin definitions, requiring no rewiring.

PCB Fine-tuning

If the domestic device uses a 5-SMD package, simply change the 7-SMD central thermal pad to 5-SMD thermal copper foil; the Gerber update can be completed in ten minutes.

Software Calibration

Read the temperature compensation coefficients from the OCXO's internal EEPROM via serial port and import them into the MCU temperature compensation table; just increment the software firmware version by +0.0.1.

Key Summary: Overview of OCXO Selection Points

- NJECBLJHNY-10.000000's measured ±5 ppb approaches the theoretical limit, but the 16-week lead time and >400 RMB unit price have become supply chain bottlenecks.

- Domestic OCXOs have achieved equivalent performance as of 2025 Q2, with lead times shortened to ≤4 weeks and expected bulk costs reduced by 40%.

- Packages are highly compatible (7-SMD and 5-SMD), hardware modification costs are extremely low, and software only requires routine temperature compensation table updates.

? Frequently Asked Questions (FAQ)

- The latest data: high-speed network equipment crystal oscillator selection failure rate of up to 35%, these five parameters are the key

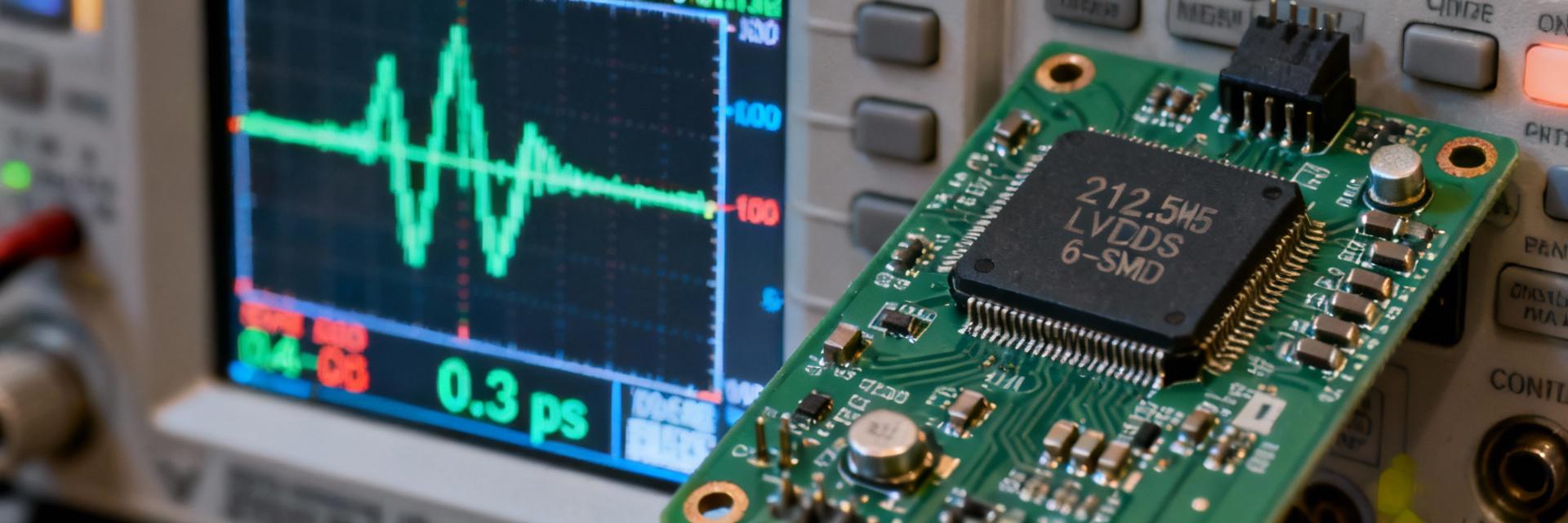

- Measured data: How to reduce clock jitter of high-speed acquisition system by 40% with 212.5MHz oscillator?

- 2025 Low Jitter Clock Selection Ultimate Guide: 5 Steps to Precisely Match High-Frequency XO and Say Goodbye to Performance Waste

- Latest Data Report: Comparison of Key Parameters for 20MHz OCXO Selection and Cost-Benefit Analysis

- The ultimate selection guide for 20MHz high-precision oscillators: 5 steps to lock in the best solution for your project

- How to accurately match the 33.333MHz CMOS crystal oscillator for your project? Five-step pit avoidance guide

- From principle to practice: How to accurately select and match a 312.5MHz LVDS oscillator for your high-speed communication system?

- Latest 312.5MHz LVDS Crystal Oscillator Selection Guide: Analysis of 5 Key Parameters from AI Acceleration Card to High-Speed Communication

- NJECAEJHNY-20.000000 OCXO failure Big data: high and low temperature cycle loss accounts for 47%

- 10 minutes to complete the selection of Taiyi ON-K series high-frequency crystal oscillators: Engineer's practical step-by-step guide

-

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP

HCPL2601Sanyo Semiconductor/onsemiOPTOISO 2.5KV OPN COLLECTOR 8DIP -

MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP

MCT6Sanyo Semiconductor/onsemiOPTOISOLATOR 5KV 2CH TRANS 8-DIP -

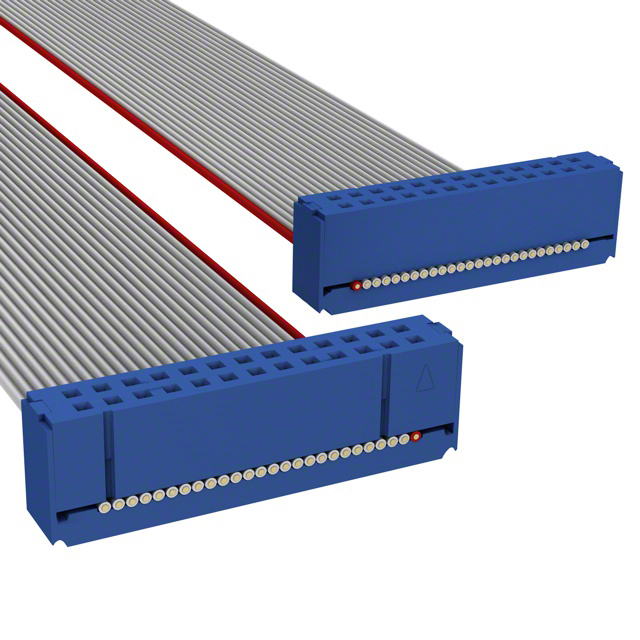

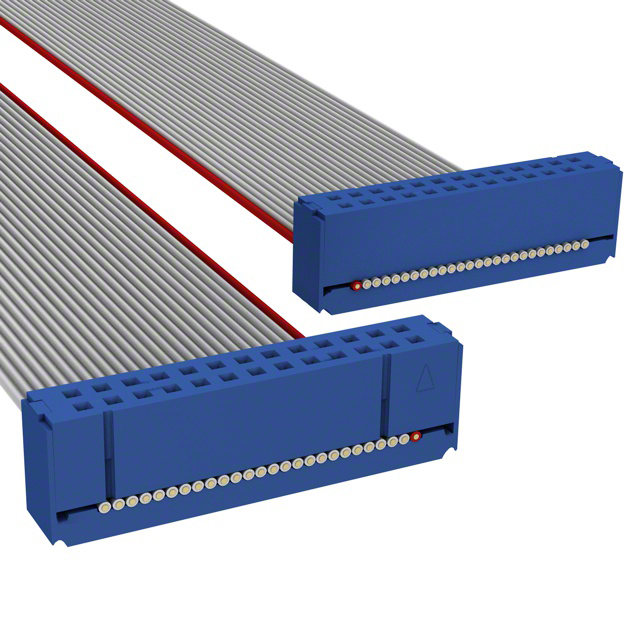

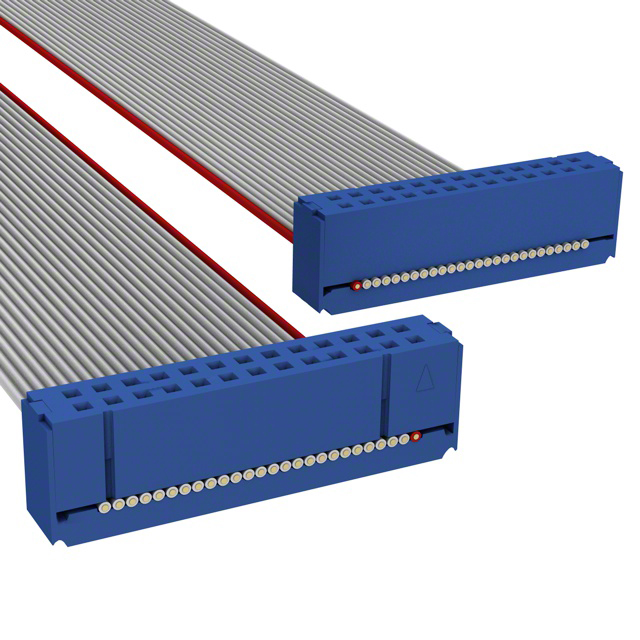

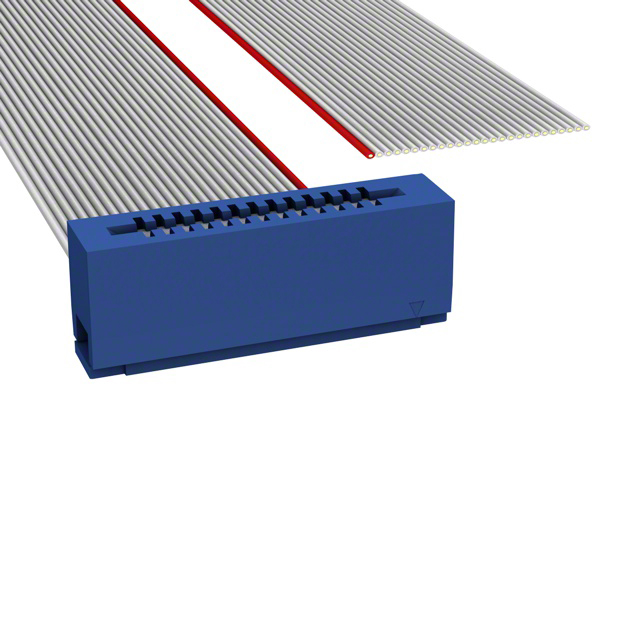

C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2636GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2618GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T

C3EET-5036GCW IndustriesIDC CABLE - CCE50T/AE50G/CCE50T -

C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G

C3AAG-2606GCW IndustriesIDC CABLE - CSC26G/AE26G/CSC26G -

C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X

C1EXG-2636GCW IndustriesIDC CABLE - CCE26G/AE26G/X -

S6008LWickmann / LittelfuseSCR 600V 8A TO220

S6008LWickmann / LittelfuseSCR 600V 8A TO220 -

CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL

CFR-12JB-52-110RYAGEORES 110 OHM 5% 1/6W AXIAL -

ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL

ECS-F1CE225KPanasonic Electronic ComponentsCAP TANT 2.2UF 20% 16V RADIAL